Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

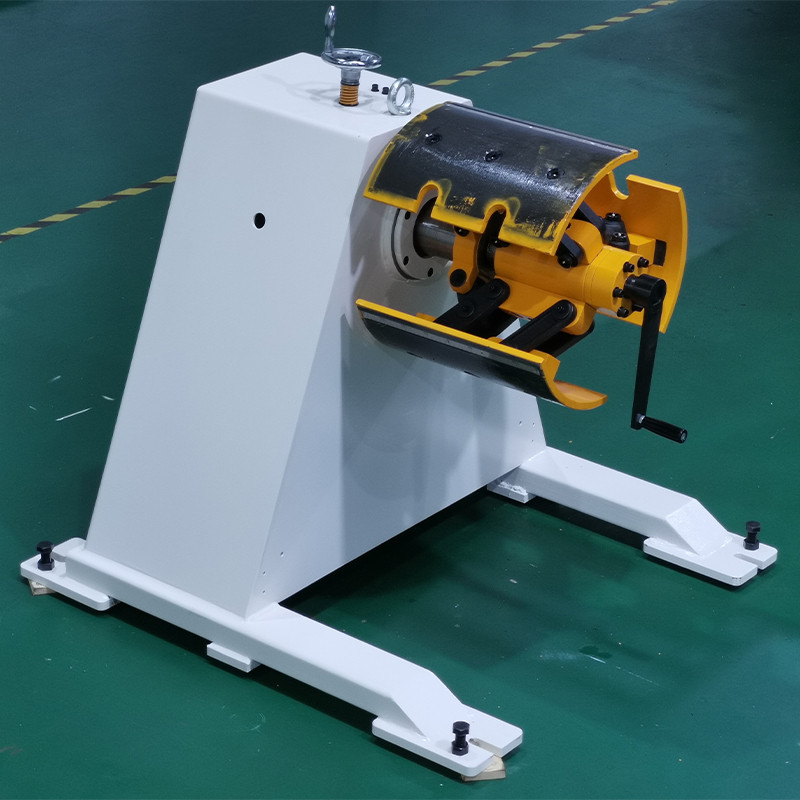

Uncoiler for cutting line in circles

time2024/01/24

- The large-scale zigzag uncoiler, developed by FANTY Machinery, addresses challenges in coil material width.

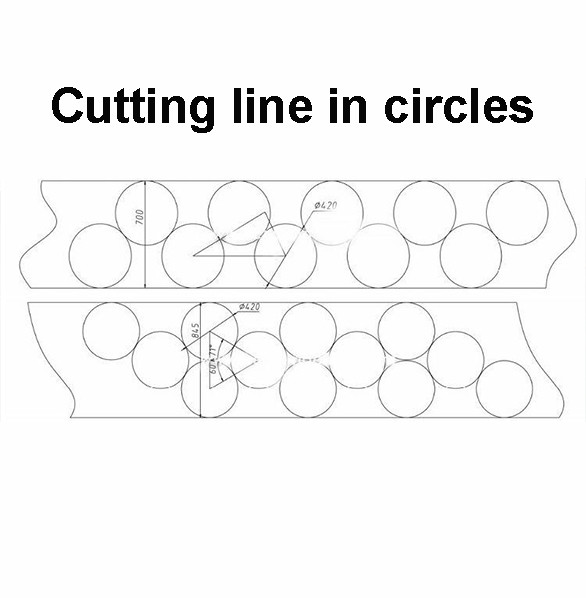

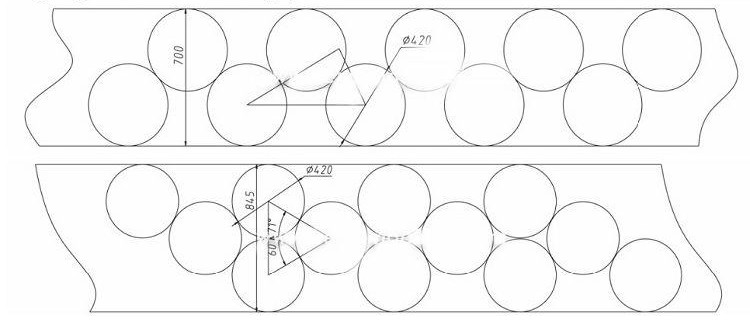

An decoiler, a straightener, and an NC zigzag servo feeder are typically included in the combo model of the servo circle cutting production line, which is specifically made for the punching and blanking of coiled sheets. The round and round cutting and increased material utilization rate are achieved by the NC zigzag servo feeder's left and right circle cutting. Additionally, it is the current wafer blanking technology that uses less energy and less material.

On the other hand, the NC zigzag servo feeder's left and right swing ranges will be very broad when the coil material is very wide. The coil will be harmed at this point if the conventional uncoiler is still in use, and the high swing range will cause inaccurate feeding. To tackle this issue on a fundamental level, FANTY Machinery specifically designed and manufactured a large-scale zigzag uncoiler. Its structural characteristic allows it to work with the NC zigzag servo feeder to produce a specific distance yaw shift when it deviates left or right. This has the benefit of minimizing the coil material's swing range, preventing coil material deterioration, and preventing incorrect feeding.

The most common uncoiler in the circle blanking line is standard motorized uncoiler.

Firstly, FANTY machine provides both hydraulic expansion uncoiler and manual expansion uncoiler depends on specific coil weight. Secondly, the uncoiler will equip a pneumatic coil hold-down arm for some springy steels.

The large-scale hydraulic pressure serves as the moving power (adjustable speed) for the large-scale zigzag uncoiler, which uses the sliding rail type displacement method. Make that the uncoiler has many settings, including disc brakes, pneumatic pushing arms, and spindle support arms, and that it moves automatically in a yaw manner during the uncoiling operation. Assure synchronization, stability, and dependability of deflection during uncoiling.

To provide a detailed introduction to its performance parameters, let's use the 1500mm large zigzag uncoiler as an example:

1. Width of coil: 100–1500 mm

2. Load: 15T (pressure support and refueling mechanism at the uncoiler's front end)

3. Using a hydraulic wedge kind of expansion

4. Φ450–Φ530 mm is the spindle expansion range.

5. Spindle drive motor: frequency converter control, AC deceleration motor

6. Double-row large-pitch chain drive is the spindle drive mode.

7. Pneumatic disc brakes as a means of spindle brake

8. Feeding from left to right on a spindle in a circular direction

9. The uncoiler's pushing arm presses the material to keep the material roll from becoming loose once the belt is removed. In order to prevent the material roll from being spread during unwinding and automatic operation, the pinch wheel revolves in tandem with the material roll's diameter at a linear speed that matches both of them.

10. Specifications for one pressure wheel made of PU rubber

11. The pressure wheel's drive mode is powered (by a deceleration motor).

12. The pressing arm has two action modes: pneumatically powered, manually lifted and lowered, and optional automatic operation.

13. ZigZag power: Powered by oil pressure, the amount of oil can be adjusted to regulate the uncoiler's yaw speed.

14. 1500 mm is the uncoiler deflection distance.

15. Frequency conversion speed regulation as the uncoiler's control mechanism

16. Control of the uncoiler: Using the induction material belt feedback signal, the material arc that is drooping can regulate the start and stop of the unwinding rack. to guarantee that the uncoiler, leveler, or feeder have a suitable and adequate buffer arc between them.

17. The main shaft's load can be increased to 15 tons thanks to a pressure support mechanism installed on its front end.

NC Zigzag Servo Feeder Working Path

For any questions, you can get in touch with us directly at fanty..........com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://..........com/@fantydecoilerfeeder

Facebook: https://..........com/Fanty1229/

Linkedin:https://..........com/company/fantydecoilerfeeder