Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Decoiler Straightener Machine for Precision Punch Press Stamping

- group name

- Decoiler Straightener for 0.4~2.2mm Steel

- Min Order

- 1 piece

- brand name

- FANTY - Stamping Automation Equipment Manufacturer

- model

- GO Series Uncoiler Cum Straightener Machine

- Nearest port for product export

- shekou, shenzhen

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T

- update time

- Wed, 24 Dec 2025 05:47:55 GMT

Paramtents

Color Standard white (other colors are available)

Payment 30% T/T as deposit, rest against shipping

Customized Service Yes

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

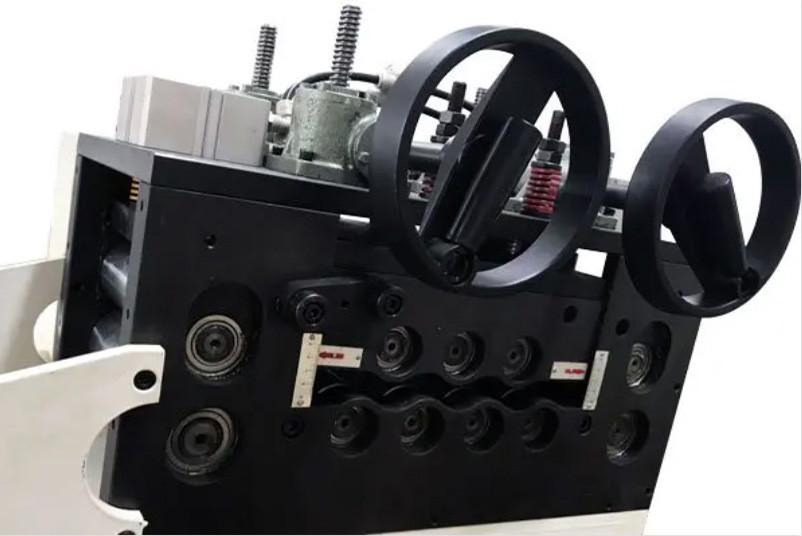

The integrated structure ensures synchronization between the decoiler and straightener. This leveling system's pneumatic rod pressing and release system on upper rollers and hand wheel roller gap adjustment give superior coil straightening outcomes than a conventional straightening machine.

Model | GO-200 | GO-300 | GO-400 | GO-500 | GO-600 |

Coil Width | 200 | 300 | 400 | 500 | 600 |

Coil Thickness | 0.4-2.2mm | ||||

Coil O.D.(mm) | Ø 450-530 | ||||

Coil I.D.(mm) | Ø 1200 | ||||

Max. load(kg) | 800 | 1000 | 1500 | 2000 | 2000 |

Expansion way | Manual | ||||

Line speed (m/min) | 0-15 | ||||

Leveling adjusting | Fine-tuning | ||||

Sensing method | Touch Sensor | ||||

Fanty machine focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

First, when you receive an uncoiler cum straightener machine, you must contact us. Our engineer will work with you to handle it. Second, before you receive the equipment, we email you the user manuals. Thirdly, our qualified specialist will instruct you online till you can effectively utilize it on your own.

1) T/T stands for a foreign bank transfer. 30% down payment; we'll build the machine for you. before shipment, 70%. It is quick and practical.

You can provide us with information such as the working piece's material, thickness, width, and other specifics. Using our expertise, we can suggest the uncoiler cum straightener machine that will work best.

Yes, we do. Before delivery, the equipment was setup and debugged. The device is immediately usable following delivery. Naturally, we could also send our technologists to your nation to install and debug the device, but there would be a cost.