Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How to Improve Product Consistency with Advanced Stamping Automation Systems?

time2025/02/13

- Explore how stamping automation systems improve product consistency in manufacturing. By integrating advanced automation technologies, manufacturers can achieve higher precision.

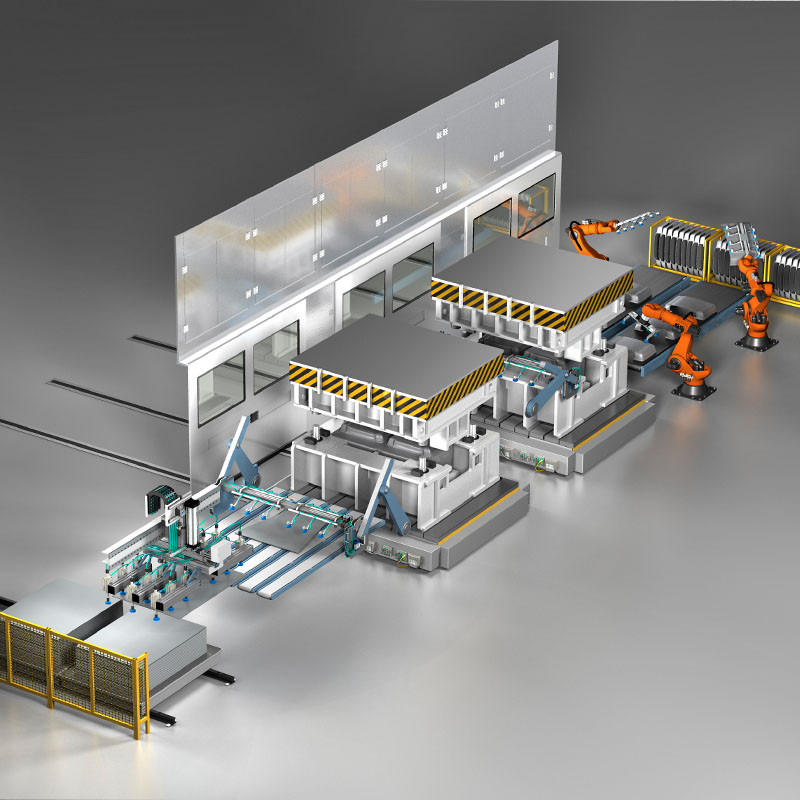

In today’s competitive manufacturing landscape, product consistency is crucial for ensuring high quality, minimizing defects, and meeting customer expectations. Advanced stamping automation systems are increasingly being utilized across industries to improve production efficiency, reduce variability, and enhance overall consistency in product output. By integrating automated controls, sensors, and precision components into stamping processes, manufacturers can achieve better dimensional accuracy, improved repeatability, and tighter tolerances, which are essential for industries like automotive, electronics, and precision engineering.

Automated systems enable manufacturers to monitor and control key variables in real-time, ensuring that each part is produced within specified tolerances. Moreover, automated stamping press machines can detect anomalies or inconsistencies early in the production cycle, allowing for immediate corrective actions and preventing quality issues from propagating downstream. This reduces scrap, waste, and costly rework, improving the overall efficiency of the production line.

One significant benefit of advanced stamping automation systems is their ability to operate consistently at high speeds while maintaining quality. In contrast, manual stamping operations may introduce variations due to human error, tool wear, or inconsistent settings. By implementing automation, manufacturers ensure that each stamp produced is of uniform quality, helping meet strict customer and regulatory standards.

Key Benefits of Stamping Automation for Consistency:

Enhanced Precision

Automated systems provide precise control over speed, pressure, and tool alignment, ensuring consistent product quality.

Reduced Variability

Real-time data collection and adjustments minimize the impact of environmental changes or operator errors.

Lower Production Costs

By reducing waste and defects, automation contributes to more efficient resource utilization and lower production costs.

To fully harness the potential of stamping automation, manufacturers must ensure their systems are properly calibrated, maintained, and integrated with other production technologies. It’s also essential to train operators and production staff to work effectively with automation to achieve the best results.