Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Why Precision Stamping Machines Are Essential for Electronics Manufacturing ?

time2025/02/13

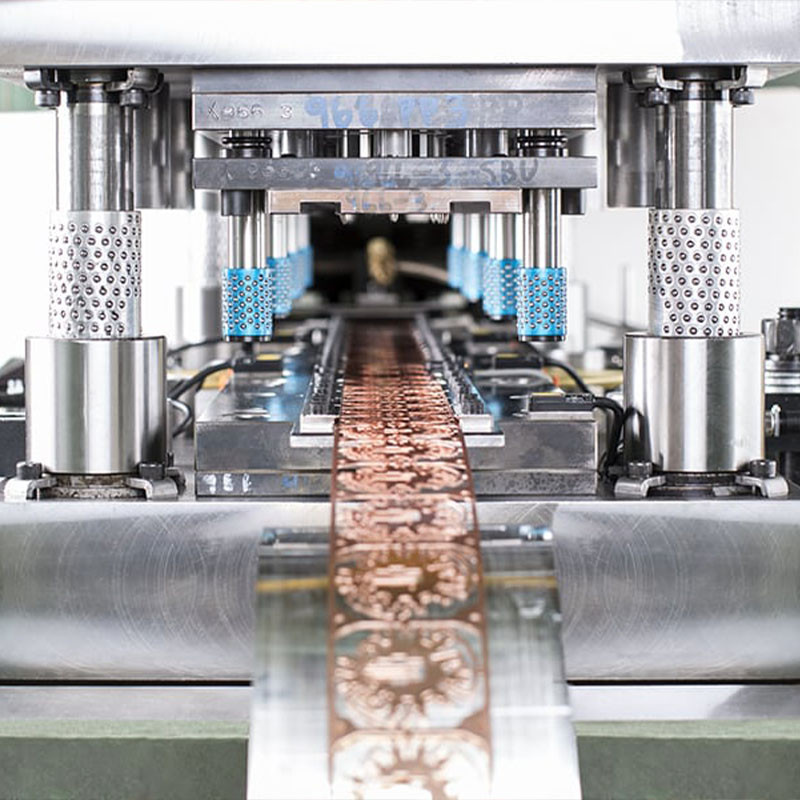

- Explore how precision stamping machines and automated stamping systems are transforming electronics manufacturing by ensuring high-quality, cost-effective, and efficient production.

In the world of electronics manufacturing, precision, consistency, and efficiency are paramount. Precision stamping machines are essential to achieving these critical qualities in the production of electronic components. With the growing demand for miniaturized electronic devices and complex component designs, manufacturers must adopt advanced technology to ensure the accuracy and reliability of their products. Automated stamping systems have become increasingly popular in meeting these needs, offering an efficient solution for high-volume production without compromising on quality.

The Role of Precision Stamping in Electronics Manufacturing

Electronics manufacturing, whether for consumer gadgets, automotive parts, or industrial electronics, requires components that are not only high-performance but also precise in their specifications. Precision stamping machines deliver these components with incredible accuracy, producing intricate parts such as connectors, switches, and housings.

These machines offer several advantages over traditional manufacturing methods, including:

1. High Precision and Accuracy

Precision stamping machines are capable of making highly detailed components with tight tolerances. This is critical in electronics where even minor defects can lead to device failure.

2. Consistency in Production

Automated stamping systems ensure that each component is made to exact specifications every time, significantly reducing variation and the likelihood of errors.

3. Improved Efficiency

By automating the stamping process, manufacturers can increase production rates, reduce lead times, and improve overall productivity. These systems are designed for continuous operation, reducing the need for manual labor and allowing manufacturers to scale production easily.

4. Cost-Effective Production

Automated precision stamping reduces labor costs and material waste. In addition, the high-speed capabilities of modern stamping machines enable manufacturers to meet the demand for large quantities of parts without sacrificing quality.

Key Applications of Precision Stamping Machines in Electronics

1. Circuit Boards:

Precision stamping is used to manufacture high-precision connectors, terminals, and leads for printed circuit boards (PCBs), crucial for all modern electronic devices.

2. Consumer Electronics:

Devices like smartphones, tablets, and wearables require small, intricate metal parts that precision stamping machines can produce with incredible detail and speed.

3. Automotive Electronics:

The automotive sector has seen significant growth in electronics, with precision stamped components used in everything from sensors to wiring connectors. These parts must withstand high stress and perform reliably under various environmental conditions.

4. Medical Devices:

Electronic components in medical devices must meet stringent standards. Precision stamping machines ensure that parts for medical electronics such as pacemakers, sensors, and diagnostic equipment are manufactured with extreme accuracy.

The Advantage of Automation in Stamping

The integration of automated stamping systems into electronics manufacturing lines has been a game-changer for the industry. Automation not only enhances the precision and consistency of the stamping process but also allows for higher production rates and cost savings.

As electronics manufacturing evolves, the demand for more complex, small, and durable components will continue to rise. Automated stamping systems provide a solution that ensures manufacturers can keep up with these demands while maintaining the quality and performance of their products.

Conclusion

In the competitive world of electronics manufacturing, precision stamping machines have become indispensable tools for ensuring product quality, reducing waste, and increasing production efficiency. The continued advancement of automated stamping systems promises to meet the growing need for high-performance electronic components. For manufacturers looking to remain competitive, investing in precision stamping is not just a choice, it’s a necessity.