Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

The Future of Stamping Automation: Trends to Watch in 2025

time2025/01/24

- The future of stamping automation in 2025 revolves around AI-driven systems, IoT connectivity, and sustainability. These trends enhance efficiency and reduce waste.

In the ever-evolving world of manufacturing, stamping automation remains at the forefront of innovation, driving efficiency, precision, and sustainability. As we step into 2025, pressing manufacturer need to stay informed about emerging trends that will shape the future of this industry. This article explores key advancements, their implications for stamping manufacturers, and how these trends can offer competitive advantages.

1. Integration of Artificial Intelligence (AI) and Machine Learning (ML)

The role of AI and ML in stamping automation is rapidly expanding. These technologies enable predictive maintenance, reducing downtime by identifying potential equipment failures before they occur. Additionally, AI-powered systems optimize production lines by analyzing data in real time, improving operational efficiency and minimizing waste.

AI integration also supports intelligent decision-making in tool design and process adjustments, ensuring consistently high-quality outputs.

2. Smart Factories and IoT Connectivity

The concept of smart factories, driven by the Industrial Internet of Things (IIoT), is transforming stamping automation. Connected devices and sensors on equipment such as stamping presses, feeders, and coil handlers provide real-time data on performance and efficiency.

This data enables manufacturers to monitor processes remotely, improve resource utilization, and quickly address inefficiencies. In 2025, more manufacturers will adopt IIoT-driven solutions to enhance transparency and streamline production.

3. Sustainable Manufacturing Practices

Sustainability is no longer optional—it’s a necessity. Stamping automation systems are evolving to incorporate energy-efficient designs and material-saving features. Closed-loop systems, regenerative drives, and eco-friendly lubricants are just some of the innovations helping manufacturers reduce their carbon footprint.

Additionally, optimized stamping processes minimize scrap and maximize material usage, contributing to sustainable production goals while reducing costs.

4. Advanced Materials in Stamping

The automotive, aerospace, and electronics industries are increasingly using lightweight and advanced materials, such as high-strength steel and aluminum alloys. In 2025, stamping automation will continue to evolve to handle these materials with precision.

Manufacturers are investing in adaptive press systems that adjust parameters like force and speed to accommodate material characteristics, ensuring consistent quality and reducing wear on equipment.

5. Flexible and Modular Automation Systems

Flexibility is key for manufacturers aiming to meet diverse customer demands. Modular automation systems allow manufacturers to adapt their production lines quickly to accommodate different product sizes, shapes, and quantities.

In 2025, advancements in flexible tooling and reconfigurable stamping cells will give manufacturers the agility needed to compete in fast-changing markets.

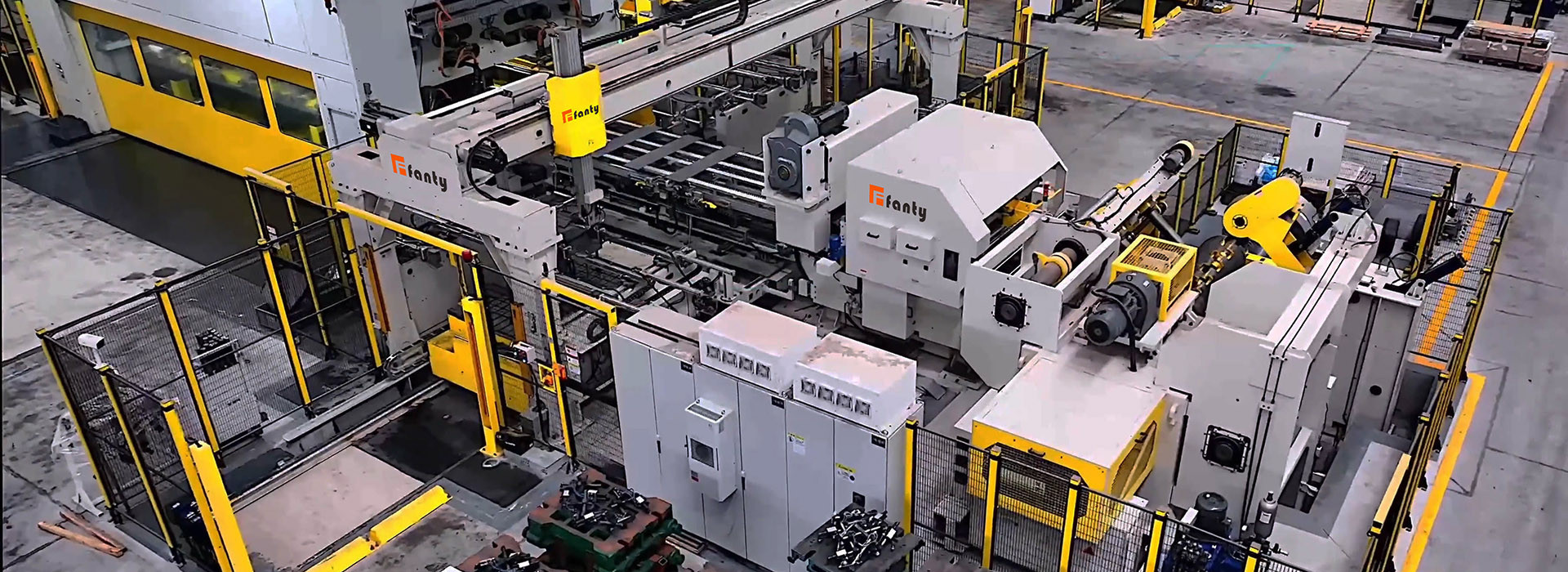

6. Robotics and Collaborative Automation

The use of robots in stamping automation is on the rise. From robotic arms for precise material handling to collaborative robots (cobots) that work alongside human operators, these technologies enhance productivity and safety.

Cobots are particularly beneficial for repetitive or dangerous tasks, reducing workplace injuries and allowing workers to focus on higher-value activities. Robotics-driven automation will continue to expand in 2025, offering scalable and cost-effective solutions for manufacturers.

7. Advanced Simulation and Digital Twins

Simulation technologies and digital twins are revolutionizing how manufacturers approach stamping automation. These tools allow manufacturers to create virtual replicas of their production lines, enabling them to test and optimize processes before implementation.

Digital twins also provide ongoing insights into system performance, facilitating continuous improvement and reducing downtime. This trend is set to grow significantly in 2025, helping manufacturers achieve higher efficiency and lower costs.

8. Customization and Industry-Specific Solutions

Manufacturers are demanding stamping automation systems tailored to their specific needs. In response, automation providers are offering industry-specific solutions, such as specialized tooling for electric vehicle components or compact systems for electronics manufacturing.

Customization ensures that stamping processes align with production goals, boosting overall productivity and competitiveness.

Conclusion

The future of stamping automation in 2025 promises significant advancements in AI integration, IoT connectivity, sustainability, and more. These trends will redefine manufacturing processes, offering increased efficiency, flexibility, and quality while addressing the demand for sustainable and adaptable solutions.

To remain competitive, manufacturers must embrace these innovations, invest in the latest technologies, and partner with trusted automation providers. By staying ahead of these trends, businesses can position themselves for long-term success in an increasingly dynamic industry.