Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How To Operate The Decoiler Straightener Feeder Machine ?

time2024/09/12

- By adhering to guidelines in this article, manufacturers can maximize the efficiency of their uncoiler straightener feeder machine leading to enhanced operational success.

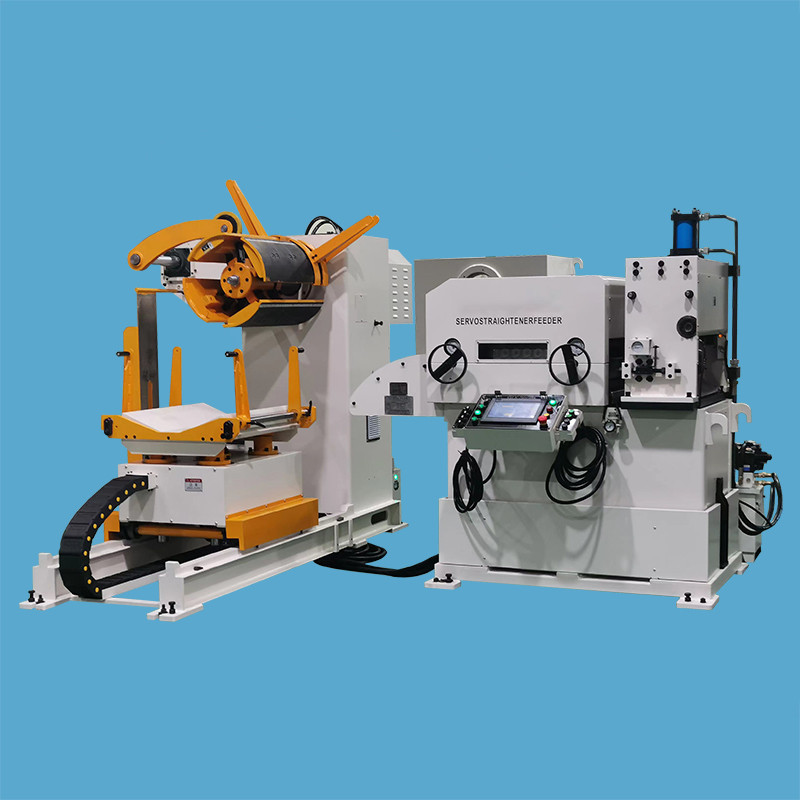

In the realm of metal processing, as the type of steel coil handling equipment, the 3-in-1 Decoiler Straightener Feeder Machine, also we called Uncoiler Straightener Feeder Machine, plays a pivotal role in streamlining operations and enhancing productivity in the automotive industry. This comprehensive guide outlines the best practices for the efficient operation of this essential machinery, ensuring optimal performance and minimal downtime.

Understanding the 3-in-1 Uncoiler Straightener Feeder Machine

The 3-in-1 decoiler straightener feeder machine integrates three critical functions: decoiling, straightening, and feeding metal strips into stamping or forming machines. This integration not only saves space but also improves workflow efficiency by reducing the need for multiple machines.

Combined decoiler part, straightener part and servo feeder part into a machine for auto parts hardware stamping !

Send us inquiry now for a detailed quotation: fanty..........com

Key Components of the 3-in-1 Uncoiler Straightener Feeder Machine

Decoiler: Unwinds the coiled metal strip, allowing for a smooth feeding process.

Straightener: Corrects any bends or curves in the metal strip, ensuring it is flat and ready for processing.

Feeder: Accurately delivers the straightened metal to the stamping or forming machine at the required speed and position.

Step-by-Step Guide to Efficient Operation

Step 1: Setup and Calibration

Before operating the 3-in-1 decoiler straightener feeder machine, proper setup and calibration are essential.

Positioning: Ensure the machine is placed on a stable surface and aligned with the stamping or forming machine.

Coil Loading: Load the metal coil onto the decoiler, ensuring it is securely fastened and properly aligned.

Calibration: Adjust the straightener settings according to the thickness and type of metal being processed. This may involve setting the gap between the rollers to achieve the desired flatness.

Step 2: Adjusting Feed Parameters

Feeding parameters must be tailored to the specific requirements of the production run.

Feed Length: Set the feed length based on the specifications of the stamping or forming operation. This ensures that the correct amount of material is fed into the machine.

Feed Speed: Adjust the feed speed to match the operational speed of the stamping or forming machine. This synchronization is crucial for maintaining efficiency and preventing jams.

Step 3: Monitoring Operation

Continuous monitoring during operation is vital for maintaining efficiency and identifying potential issues.

Visual Inspection: Regularly check for any signs of misalignment or irregular feeding. Address any issues immediately to prevent downtime.

Performance Metrics: Keep track of key performance indicators such as feed accuracy, speed, and material waste. This data can help identify areas for improvement.

Step 4: Maintenance and Troubleshooting

Regular maintenance is essential for the longevity and efficiency of the 3-in-1 decoiler straightener feeder machine.

Routine Checks: Conduct routine inspections of all components, including the decoiler, straightener, and feeder. Look for wear and tear, and replace parts as necessary.

Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

Troubleshooting: In case of operational issues, refer to the machine’s manual for troubleshooting steps. Common issues may include feeding jams, misalignment, or inconsistent straightening.

Benefits of Efficient Operation

Increased Productivity: Streamlined operations lead to higher output and reduced cycle times.

Cost Savings: Efficient use of materials and reduced downtime contribute to lower operational costs.

Improved Product Quality: Consistent feeding and straightening result in higher quality finished products.

Conclusion

The efficient operation of the 3-in-1 decoiler straightener feeder machine is crucial for optimizing metal processing workflows. By following the step-by-step guide outlined in this article, manufacturers can enhance productivity, reduce costs, and improve product quality. Implementing these best practices will ensure that your operations remain competitive in the ever-evolving manufacturing landscape.

Contact us fanty..........com for a quotation now !