Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How To Optimize Your Stamping Production Line With High-Speed Roller Feeders and NC Servo Feeders ?

time2024/09/12

- By the insights provided in this article, manufacturers can position themselves for success in an increasingly competitive market by choose a right press feeder.

In the competitive landscape of manufacturing, optimizing your stamping production line is crucial for enhancing efficiency, reducing costs, and improving product quality. This guide delves into the intricacies of 2 types press feeders: high-speed roll feeders and NC servo feeders, providing insights that can significantly elevate your production capabilities.

Understanding Stamping Production Lines

Stamping production lines are integral to various industries, including automotive, electronics, and consumer goods. These lines utilize stamping presses to shape and cut materials, often metal, into desired forms. The efficiency of these lines is heavily influenced by the feeding mechanisms employed.

The Role of Press Feeders in Stamping

Press Feeders are essential components in stamping production lines, responsible for delivering material to the press at the correct speed and alignment. The choice of feeder can impact cycle times, material waste, and overall production efficiency.

High-Speed Roll Feeders: An Overview

High-speed roll feeders are designed to handle large volumes of material with precision and speed. They utilize rollers to grip and transport material, ensuring consistent feeding into the stamping press.

Advantages of High-Speed Roll Feeders

Increased Throughput: High-speed roll feeders can significantly enhance the throughput of your production line, allowing for faster cycle times and increased output.

Reduced Material Waste: With precise feeding, these feeders minimize the risk of material wastage, leading to cost savings.

Versatility: They can handle a variety of materials and thicknesses, making them suitable for diverse applications.

Key Features to Consider

Speed Control: Look for feeders with adjustable speed settings to optimize performance based on material type and production requirements.

Durability: High-quality materials and construction are essential for longevity and reliability in high-speed operations.

Ease of Maintenance: Select feeders that are easy to maintain, ensuring minimal downtime during production.

NC Servo Feeders: Precision and Control

NC servo feeders utilize advanced servo motor technology to provide precise control over the feeding process. This technology allows for accurate positioning and timing, which is critical in high-speed stamping operations.

Benefits of NC Servo Feeders

Precision Feeding: NC servo feeders offer unparalleled accuracy, ensuring that materials are fed into the press with exact timing and alignment.

Programmable Settings: These feeders can be programmed for various materials and production runs, enhancing flexibility in manufacturing.

Reduced Setup Time: Quick adjustments and programming capabilities lead to shorter setup times between production runs.

Essential Features of NC Servo Feeders

User-Friendly Interface: A simple interface allows operators to easily program and adjust settings.

Feedback Systems: Integrated feedback mechanisms ensure that the feeder operates within specified parameters, enhancing reliability.

Energy Efficiency: NC servo feeders are designed to consume less energy, contributing to lower operational costs.

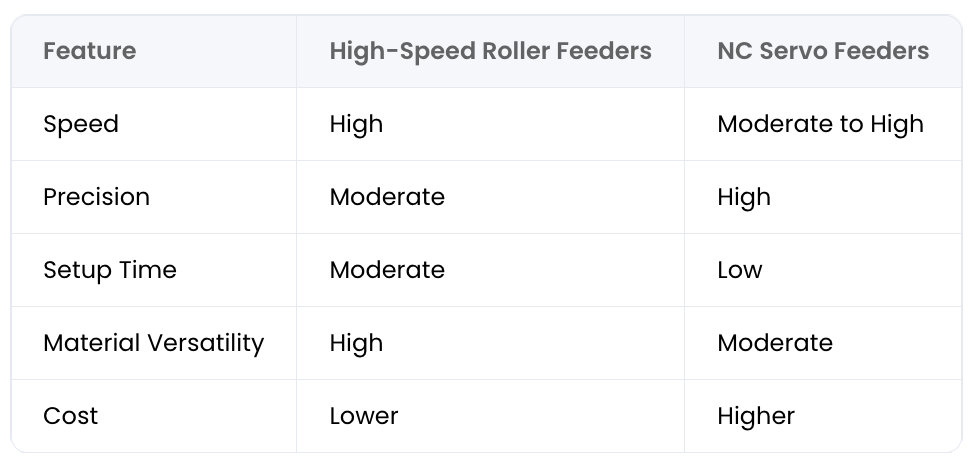

Comparing High-Speed Roller Feeders and NC Servo Feeders

Implementing Feeders in Your Production Line

When integrating high-speed roller feeders or NC servo feeders into your stamping production line, consider the following steps:

Assess Your Needs: Evaluate your production requirements, including material types, thicknesses, and desired output.

Choose the Right Press Feeder: Based on your assessment, select the feeder that best aligns with your operational goals.

Train Your Team: Ensure that your operators are well-trained in the operation and maintenance of the chosen feeders.

Monitor Performance: Continuously monitor the performance of your feeders to identify areas for improvement and optimization.

Conclusion

Optimizing your stamping production line through the strategic use of high-speed roll feeders and NC servo feeders can lead to significant improvements in efficiency, precision, and cost-effectiveness. By understanding the unique advantages and features of each feeder type, manufacturers can make informed decisions that enhance their production capabilities.