Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

What Are The Advantages of Automatic Feeding and Shearing Production Line

time2024/09/09

- The benefits of automatic feeding and shearing production lines are clear in this article

In the ever-evolving landscape of manufacturing, the integration of advanced technologies has become paramount. One of the most significant advancements in the sheet metal industry is the implementation of automatic feeding and shearing production lines. Normally, a complete feeding and shearing production line includes, decoiler, also called uncoiler machine +straightener +press feeder+ shearing machine + punch press. This article delves into the myriad benefits these systems offer, enhancing efficiency, precision, and overall productivity.

Enhanced Efficiency in Production

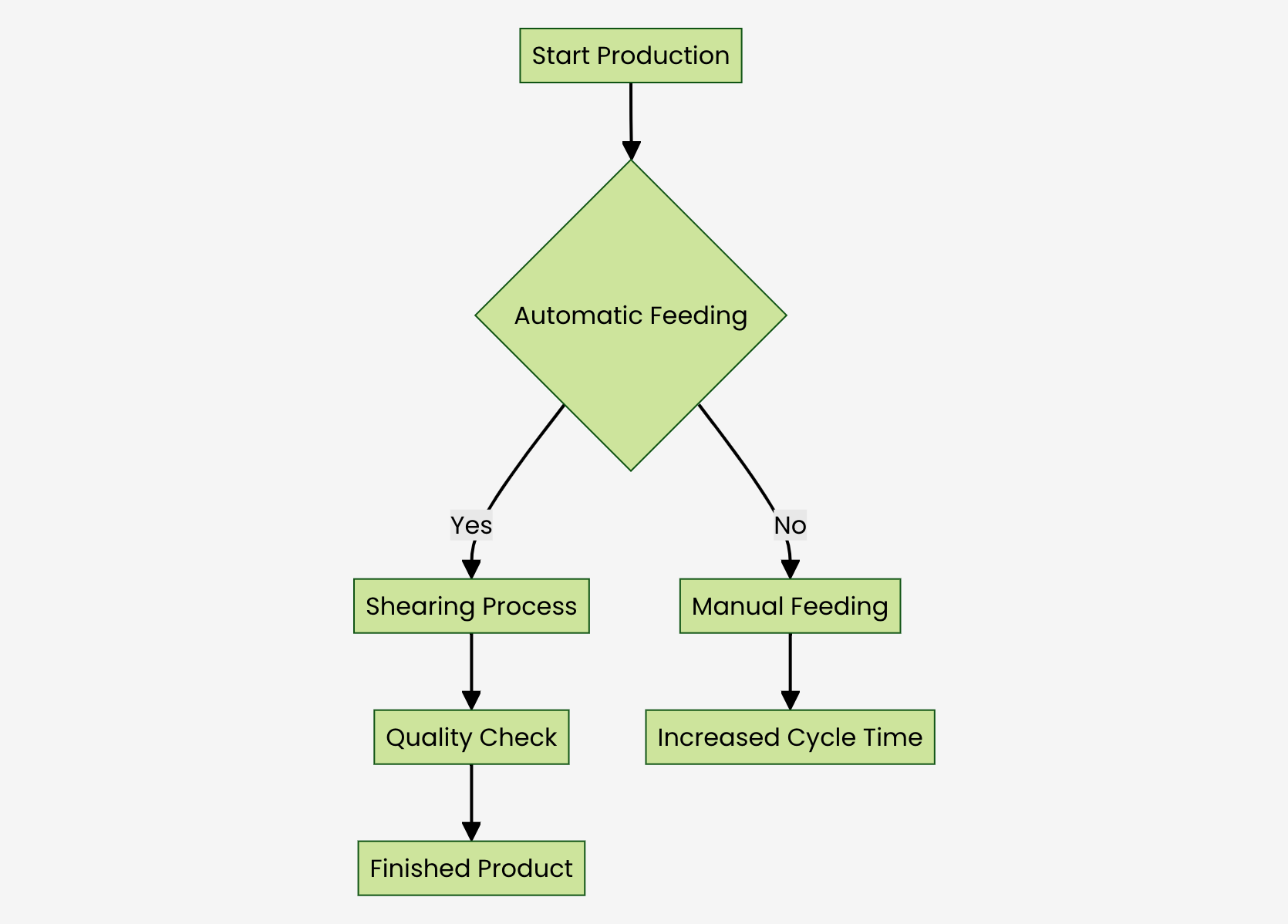

Automatic feeding and shearing production lines streamline the manufacturing process, significantly reducing cycle times. By automating the feeding of raw materials into the shearing machine, manufacturers can achieve continuous operation without the need for manual intervention. This not only accelerates production rates but also minimizes downtime associated with material handling.

Key Efficiency Metrics

* Reduced Cycle Time: Automation can cut down the time taken for each shearing operation, allowing for more parts to be produced in a shorter timeframe.

* Consistent Output: Automated systems ensure that the feeding process is uniform, leading to consistent quality in the final products.

Precision and Quality Control

One of the standout features of automatic feeding and shearing production lines is their ability to maintain high levels of precision. These systems are equipped with advanced sensors and control mechanisms that ensure each cut is executed with exacting accuracy. This precision is crucial in industries where tolerances are tight, and any deviation can lead to costly errors.

Benefits of Precision

* Reduced Waste: Accurate cuts minimize material wastage, leading to cost savings and more sustainable practices.

* Improved Product Quality: Consistent precision enhances the overall quality of the finished products, meeting stringent industry standards.

Cost-Effectiveness

Investing in automatic feeding and shearing production lines can lead to significant cost savings over time. While the initial investment may be substantial, the long-term benefits far outweigh the costs. Automation reduces labor costs, minimizes material waste, and increases production efficiency, all contributing to a healthier bottom line.

Long-Term Financial Benefits

* Lower Labor Costs: With automation, fewer operators are needed, allowing companies to allocate resources more effectively.

* Decreased Material Waste: Enhanced precision leads to less scrap material, further reducing costs.

Flexibility and Scalability

Modern automatic feeding and shearing systems are designed with flexibility in mind. They can easily adapt to different sheet metal sizes and thicknesses, making them suitable for a wide range of applications. This adaptability is crucial for manufacturers looking to diversify their product offerings without significant reconfiguration of their production lines.

Scalability Features

* Quick Changeover: Automated systems allow for rapid changeover between different production runs, facilitating a more agile manufacturing process.

* Integration with Other Technologies: These systems can be integrated with other automated processes, such as CNC machining and robotic handling, creating a seamless production environment.

Conclusion

The adoption of automatic feeding and shearing production lines represents a significant leap forward in the sheet metal manufacturing industry. By enhancing efficiency, precision, and cost-effectiveness, these systems not only improve production capabilities but also position manufacturers for future growth. As the industry continues to evolve, embracing such technologies will be essential for staying competitive in a rapidly changing market.

In summary, the benefits of automatic feeding and shearing production lines are clear: they offer a pathway to increased productivity, reduced costs, and improved product quality, making them an indispensable asset for modern manufacturers.

Need Customize you automatic feeding and shearing production lines ?

Contact us: fanty..........com