Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How To Optimize Your Stamping Process with a Heavy Duty Decoiler ?

time2024/09/06

- As An uncoiler machine, by leveraging the capabilities of a heavy duty decoiler, manufacturers can enhance their stamping processes, leading to increased productivity and superior product quality.

As the steel coil handling equipment, uncoiler machine plays a important role in the press line. In the realm of metal stamping, efficiency and precision are paramount. One of the most effective ways to enhance these aspects is by integrating a heavy duty decoiler into your stamping operations. This article delves into the benefits and strategies for optimizing your stamping process using this type decoiler.

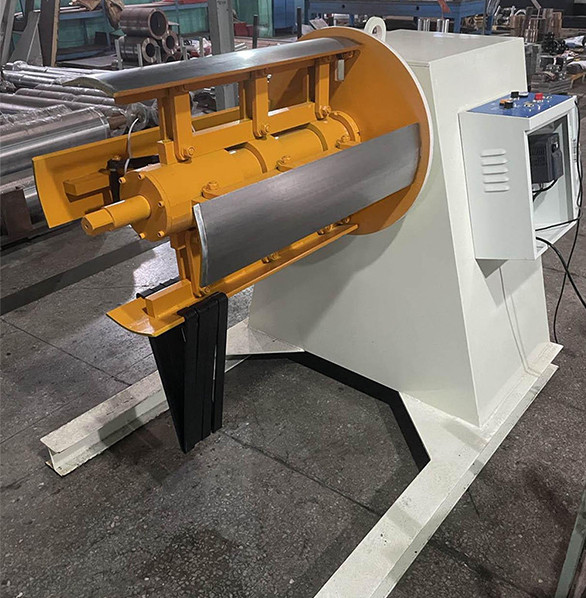

What is a Heavy Duty Decoiler?

A heavy-duty decoiler is a robust machine designed to unwind large coils of metal with ease and precision. Unlike standard decoilers, heavy-duty models are built to handle heavier materials and larger coil sizes, making them ideal for high-volume production environments.

Contact us for more details: fanty..........com

Key Features of Heavy Duty Decoilers

High Load Capacity: Capable of handling heavier coils, ensuring that your production line can accommodate various material types.

Durable Construction: Built with high-quality materials to withstand the rigors of continuous operation.

Advanced Tension Control: Maintains consistent tension on the material, preventing slippage and ensuring a smooth feed into the stamping machine.

User-Friendly Controls: Equipped with intuitive controls for easy operation and adjustments.

Benefits of Using a Heavy Duty Decoiler in Stamping

1. Enhanced Production Efficiency

Heavy-duty decoilers allow for a continuous and reliable feed of material, significantly reducing downtime associated with manual loading and unloading. This leads to increased production rates and improved overall efficiency.

2. Improved Material Handling

With the ability to handle larger and heavier coils, heavy-duty decoilers minimize the risk of material damage during the feeding process. This results in less waste and higher quality stamped products.

3. Consistent Feed Rate

The advanced tension control systems in heavy-duty decoilers ensure that the material is fed into the stamping machine at a consistent rate. This precision is crucial for maintaining the quality of the stamped parts and reducing defects.

4. Reduced Labor Requirements

By automating the decoiling process, manufacturers can decrease their reliance on manual labor, leading to lower labor costs and a more streamlined operation.

Steps to Optimize Your Stamping Process with a Heavy Duty Decoiler

Step 1: Evaluate Your Current Stamping Process

Begin by assessing your existing stamping operations. Identify any bottlenecks or inefficiencies that could be addressed with the integration of a heavy-duty decoiler.

Step 2: Select the Right Heavy Duty Decoiler

Choose a heavy-duty decoiler that aligns with your specific production needs. Consider factors such as coil weight, material type, and the required feed rate to ensure optimal performance.

Step 3: Implement Proper Training

Train your staff on the operation and maintenance of the heavy-duty decoiler. Proper training will maximize the benefits of the equipment and minimize the risk of operational issues.

Step 4: Monitor Performance and Make Adjustments

After implementing the heavy-duty decoiler, continuously monitor its performance. Make necessary adjustments to optimize the feeding process and ensure it meets your production goals.

Conclusion

Integrating a heavy-duty decoiler into your stamping process can lead to significant improvements in efficiency, material handling, and product quality. By understanding the benefits and following the outlined steps, manufacturers can optimize their stamping operations and achieve greater success in the competitive landscape of metal stamping.

Contact us for customized your press line: fanty..........com.