Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

The Essential Role of Heavy-Duty Decoiler in Oscillating Stamping Lines

time2024/09/05

- Heavy-duty decoiler is essential in optimizing metalworking production, especially in oscillating stamping lines. This type uncoiler enhance workflow efficiency, improve material handling.

In the competitive landscape of metalworking, optimizing production processes is crucial for enhancing efficiency and reducing costs. One of the key components that significantly contribute to this optimization is the use of heavy-duty Decoilers in oscillating stamping lines. This article explores the vital role of this type uncoiler plays in improving workflow, material handling, and overall production efficiency. Let's explore this type heavy-duty decoiler below:

Understanding Heavy-Duty Decoilers

What's a heavy-duty decoiler ?

Heavy-duty Decoiler is a robust storage solution designed to support and organize materials in industrial settings. In oscillating stamping lines, this type uncoiler facilitate the efficient storage and retrieval of raw materials, ensuring a smooth production flow. Its design accommodates various material sizes and weights, making them indispensable in metalworking operations.

Key Features of Heavy-Duty Decoilers

Durability: Constructed from high-strength materials, this uncoiler can withstand heavy loads and harsh industrial environments.

Versatility: They can be configured to store different types of materials, including sheets, coils, and bars, providing flexibility in material management.

Space Optimization: Heavy-duty racks maximize vertical space, allowing for efficient use of floor space in production facilities.

Advantages of Heavy-Duty Decoilers in Oscillating Stamping Lines

1. Improved Workflow Efficiency

Heavy-duty decoilers streamline the workflow in oscillating stamping lines by providing easy access to materials. This accessibility reduces the time operators spend searching for materials, leading to faster setup times and increased production rates.

2. Enhanced Material Handling

The robust design of heavy-duty racks ensures safe and efficient handling of materials. With proper organization, the risk of material damage during storage and retrieval is minimized. This is particularly important in stamping operations where material integrity is critical.

3. Increased Safety

By organizing materials in a structured manner, heavy-duty decoilers contribute to a safer working environment. They reduce clutter and the risk of accidents, allowing operators to navigate the workspace more easily. Additionally, the stability of these racks prevents tipping or collapsing under heavy loads.

4. Cost-Effectiveness

Investing in heavy-duty decoilers can lead to significant cost savings over time. By optimizing storage and improving workflow efficiency, manufacturers can reduce labor costs and minimize material waste. The durability of these racks also means lower replacement and maintenance costs.

5. Flexibility in Production

Heavy-duty material racks can be easily reconfigured to accommodate changing production needs. As manufacturers adapt to new projects or materials, these racks provide the flexibility required to support diverse production requirements.

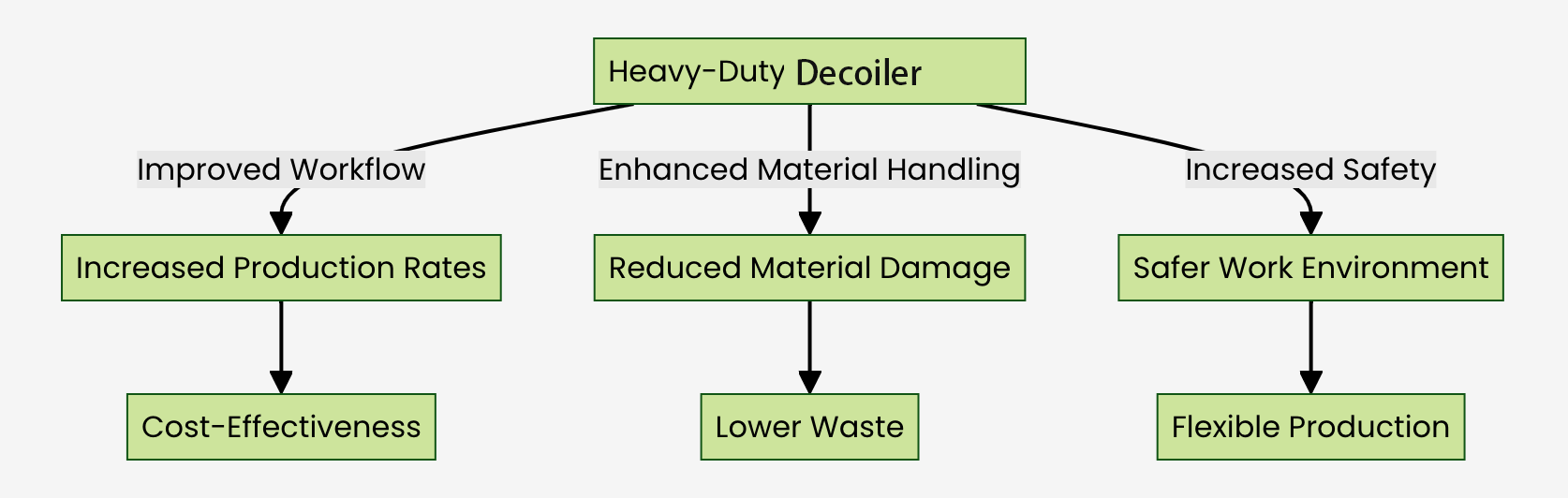

Diagram: The Role of Heavy-Duty Decoilers in Production Workflow

Conclusion

Heavy-duty decoilers are a critical component in optimizing metalworking production, particularly in oscillating stamping lines. Their ability to enhance workflow efficiency, improve material handling, and increase safety makes them an invaluable asset in any manufacturing facility. As industries continue to seek ways to streamline operations and reduce costs, the implementation of heavy-duty decoilers will play a pivotal role in achieving these goals.

By investing in these robust storage solutions, manufacturers can not only improve their production capabilities but also ensure a safer and more organized working environment, ultimately leading to greater success in the competitive metalworking industry.