Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Knowing the Heavy Duty Decoiler: Essential Parts and Function

time2024/07/31

- Lean the Essential Parts and Function of Heavy Duty Decoiler Machine in This Article.

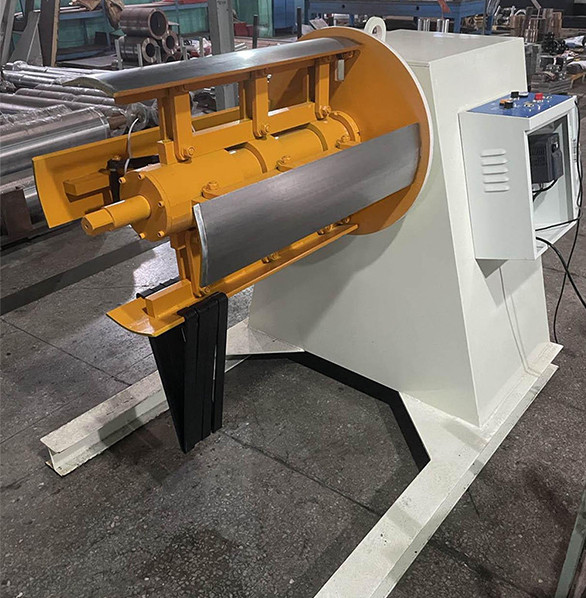

As one type decoiler machine, Within the manufacturing industry, the heavy duty decoiler is a crucial piece of steel coil handling equipment for uncoiling vertical expansion and contraction. However, familiarity frequently only encompasses its fundamental functions, leaving a large vacuum in understanding its complex architecture and guiding ideas. This lack of expertise results in inadequate maintenance procedures, which eventually cause a chain reaction of problems.

Revealing the Architecture: Heavy-Duty Decoiler Parts

1. The Structure

Fundamentally, the heavy-duty decoiler machine has a sturdy frame made of regular H-shaped steel, however manufacturers frequently utilize I-beams as well. The frame, which has rounded corners, gives the entire device a strong basis. Carefully welded from steel plates, it has bearing support points that are positioned for maximum longevity. After the welding process, the surface is carefully polished, stress-relieved, and then bearing holes are precisely machined using cutting-edge CNC machinery.

2. The Mechanism of Drive

The motor and worm gear reducer are the driving mechanism's fundamental components, and they are located inside the base enclosure. Smooth and effective operation is ensured by a system of belts and pulleys connected to the shaft, which facilitates power transmission seamlessly.

3. The System of Expansion and Contraction

The heavy-duty decoiler's drum-shaped expansion and contraction mechanism is essential to its operation. It consists of a shaft with a threaded hole on one end and a sliding sleeve covering it. Attached to the end of the sleeve is an adjustment bolt that threads into the threaded aperture. The sleeve is surrounded by rotating rods, each of which has a support tile plate fastened to its opposite end. The shaft is adorned with guide baffles that have waist holes to allow for accurate adjustment. Blocking blocks are used to stiffen the protruding blocks on one end of the support plate so that they do not accidentally shift and line up with the waist holes. By manipulating the adjusting bolt, the support plate's distance from the shaft can be adjusted, providing the best possible adaption to a variety of coil inner diameters.

4. The System of Electrical Control

The electrical control system is located next to the equipment and consists of an electrical control box and, for models larger than 500, an induction frame. Important parts including transformers, time relays, AC contactors, and switch buttons are located inside the control box. Through insulating pads, the induction rod is attached to the heavy material rack's frame discharge port. Induction lines connect the induction rod to the control box. The induction start and stop functions of the machine may be precisely controlled with this arrangement.

Improving Maintenance Procedures and Operational Intelligence

By elucidating the intricacies of the heavy-duty decoiler’s structure and functionality, manufacturers empower themselves with the requisite knowledge to optimize its operation, utilization, and maintenance. Armed with a comprehensive understanding, enterprises can proactively address maintenance needs, thereby mitigating the likelihood of untimely malfunctions and ensuring prolonged operational efficiency.

Learn About Fanty Machinery

Hardware, automotive parts press punch lines, automotive metal stamping components, saw blade manufacturing, high speed rotor and stator stamping and lamination, eyelet stamping lines, etc. are some of Fanty Machinery's specializations.

To assist nearby steel manufacturers in realizing the value of automated steel coil handling production, Fanty Machinery is dedicated to offering premium decoiler, leveling machine, press feeder, press punch, and customized punch and press line solutions. Our work is helping an increasing number of firms modernize and enhance their metal stamping lines. Additionally, Fanty Machinery has grown its business by exporting its equipment to more than 30 nations, solidifying its position as the industry leader in steel coil handling. Learn our story for more.

Contact us for a quotation: fanty..........com