Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Understanding the Importance of Decoiler Machine in the Manufacturing Industry

time2024/07/15

- Decoilers are essential as steel coil handling equipment in manufacturing, streamlining material handling, enhancing flexibility, improving efficiency, and ensuring quality.

Decoiler machine plays a crucial role as a type steel coil handling equipment in the manufacturing industry by facilitating the efficient unwinding of material rolls for various production processes. These essential components are instrumental in ensuring smooth material feeding, reducing downtime, and enhancing overall operational efficiency in manufacturing operations. In this comprehensive guide, we delve into the significance of decoilers and their impact on streamlining production workflows to meet the demands of modern manufacturing environments.

Streamlining Steel Coil Handling with Decoiler

Decoiler serve as the initial point of contact in the steel coil handling process, where raw material rolls are unwound and prepared for downstream processing stages. By effectively unwinding material rolls, decoiler eliminates potential material jams, wrinkles, and misfeeds, ensuring a continuous and uninterrupted supply of materials to production equipment. This seamless material handling capability not only enhances operational efficiency but also minimizes waste and optimizes production output in manufacturing facilities.

Enhancing Production Flexibility and Versatility

The versatility of decoiler enables manufacturers to process steel coil smoothly. By accommodating different steel roll sizes and configurations, decoiler offers production flexibility, allowing manufacturers to adapt to changing steel coil requirements and production schedules. This versatility enhances operational agility, enabling manufacturers to meet diverse customer demands and explore new opportunities in the competitive manufacturing landscape.

Improving Workflow Efficiency and Productivity

Efficient steel roll unwinding is essential for maintaining a smooth and continuous production flow, minimizing downtime, and maximizing overall productivity in manufacturing operations. By automating the unwinding process and integrating advanced control systems, decoilers optimize material feeding speeds, tension control, and alignment accuracy, ensuring consistent and reliable performance throughout the production cycle. This improved workflow efficiency translates into higher throughput, reduced lead times, and enhanced operational performance for manufacturers seeking to streamline their production processes.

Ensuring Quality and Consistency in Production

The precision and reliability of decoiler machine plays a critical role in ensuring the quality and consistency of manufactured products. By unwinding steel rolls with precision and uniformity, decoilers help maintain tight tolerances, prevent material defects, and uphold product quality standards in manufacturing operations. This attention to detail and consistency is essential for producing high-quality end products that meet customer expectations and regulatory requirements, reinforcing the importance of decoiler in achieving manufacturing excellence.

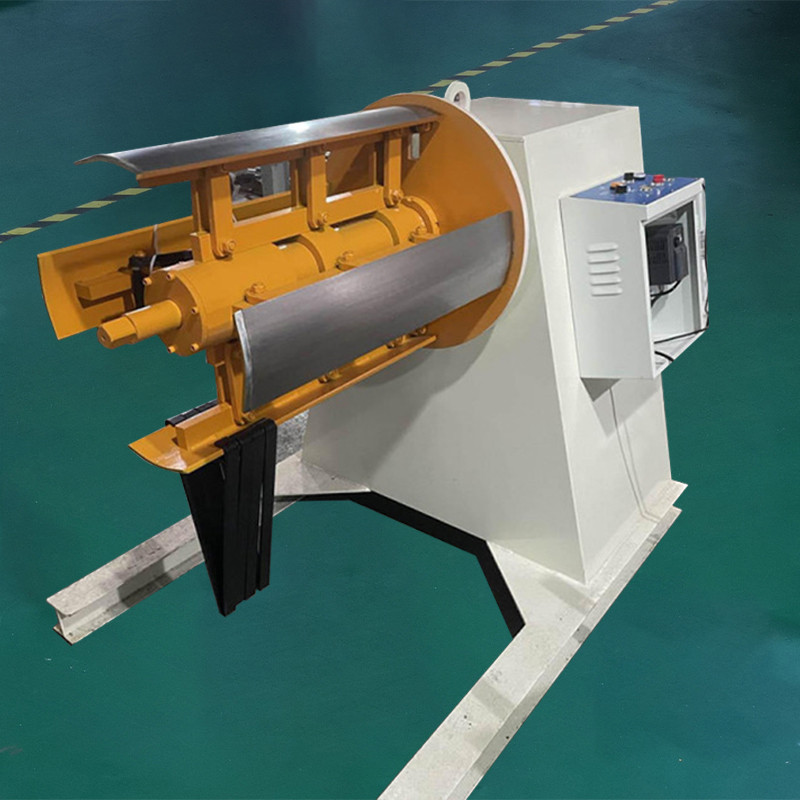

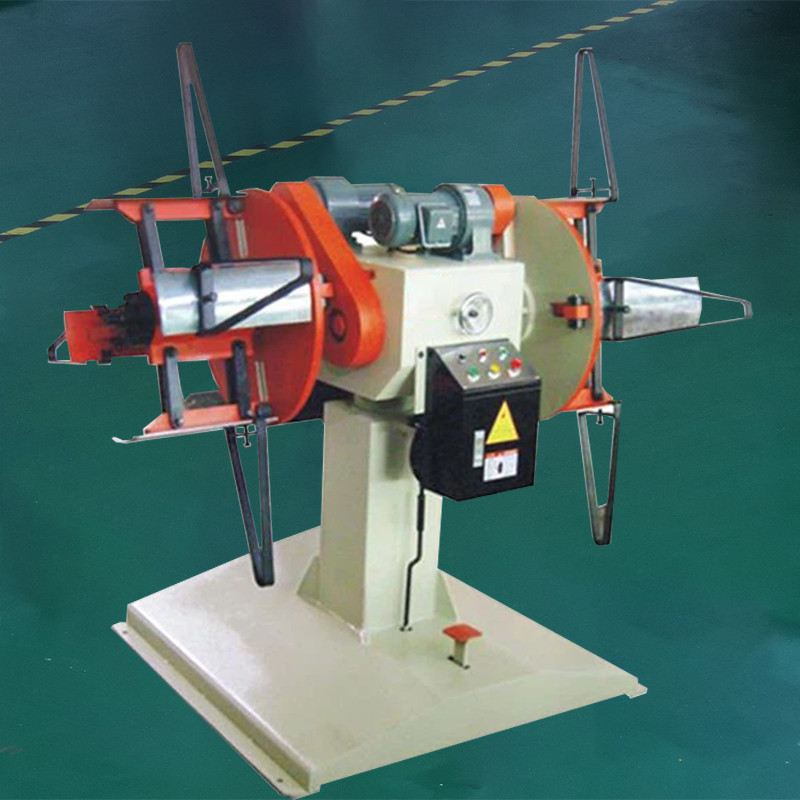

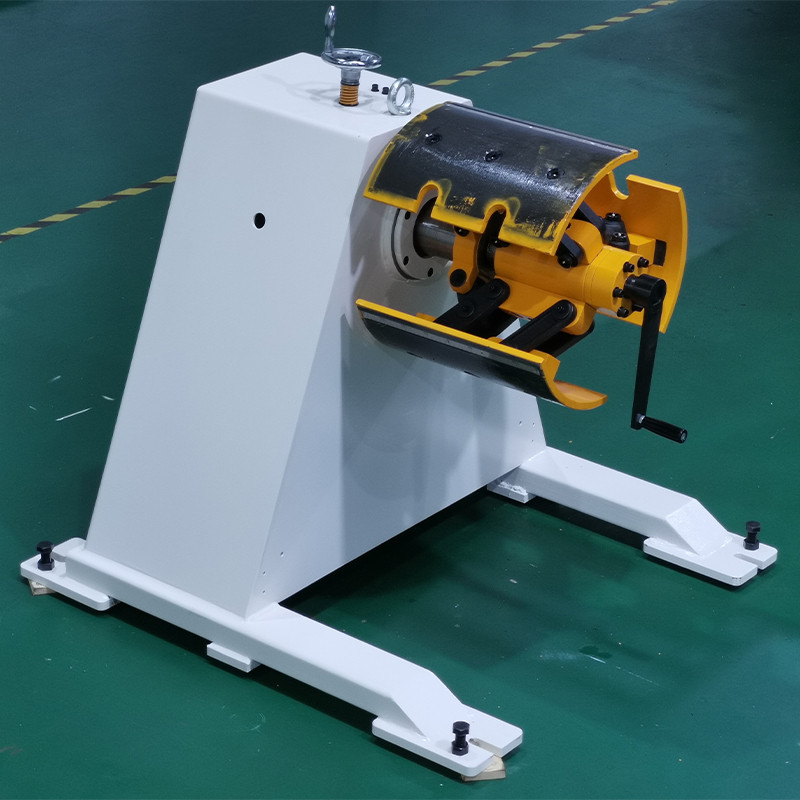

Fanty Machinery Decoilers for sale

Material thickness: 0.1mm~1.0mm

Steel strip width: 0.1mm~150mm

Coil loading weight: <2500kgs

Material Type: Steel, Aluminum, Cooper etc

Coil line Type: High speed

Coil Width: 200mm~600mm

Coil Thickness: 0.1~3.0mm

Coil Loading Weight: 1~5 Ton

Coil I.D. : Ø508mm

Coil O.D.: Ø1200mm

Coil Width: 70 mm~1200 mm

Coil Thickness: 0.5 mm~4.5 mm (6.0 mm optional)

Coil Loading Weight: 10TONS~20TONS

Coil Car: yes

Uncoiling Speed (per minute): 0~16m

Coil Width: 200 mm~500 mm

Coil Thickness: 0.35 mm – 1.6 mm

Coil I.D.: Ø450~530mm

Coil O.D.: Ø1200mm

Coil Loading Weight: 500~1500kgs per side

Mandrel Expansion: Hydraulic Expansion

Coil Width: 200 mm~600 mm

Coil Thickness: 0.35 mm – 1.6 mm

Coil I.D.: Ø450~530mm

Coil O.D.: Ø1200mm

Coil Loading Weight: 500 kgs~2000 kgs

Mandrel Expansion: Manual Expansion

As decoiler machine manufacturer for over 10 years, we also provide the NC Servo Feeder, Decoiler Straightener, Decoiler Straightener Feeder and Punch press. Learn us.

Contact us for customizing your press line: fanty..........com

Conclusion

In conclusion, the importance of decoiler machine in the manufacturing industry cannot be overstated, as these essential components play a pivotal role in optimizing steel coil handling, enhancing production flexibility, improving workflow efficiency, and ensuring quality and consistency in production processes. By investing in advanced decoiler and best practices, manufacturers can streamline their operations, boost productivity, and stay competitive in an ever-evolving manufacturing landscape. Embracing the significance of decoiler machine is key to unlocking operational efficiencies, driving innovation, and achieving sustainable growth in today's dynamic manufacturing environment.