Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

What Are The Advancements of High-Speed NC Servo Feeders ?

time2024/06/27

- High-speed NC servo feeders revolutionize industrial feeding with speed, precision, and efficiency, optimizing workflows and driving innovation.

In the fast-paced world of industrial manufacturing, high-speed feeding plays a pivotal role in enhancing productivity and efficiency. And coil feeder is play a important role during the high speed feeding line. The advancements in high-speed NC servo feeders have revolutionized the feeding process, offering unparalleled speed, precision, and reliability. Understanding the transformative impact of these cutting-edge technologies is essential for companies seeking to stay ahead in the competitive landscape of modern manufacturing.

The Evolution of High-Speed NC Servo Feeders

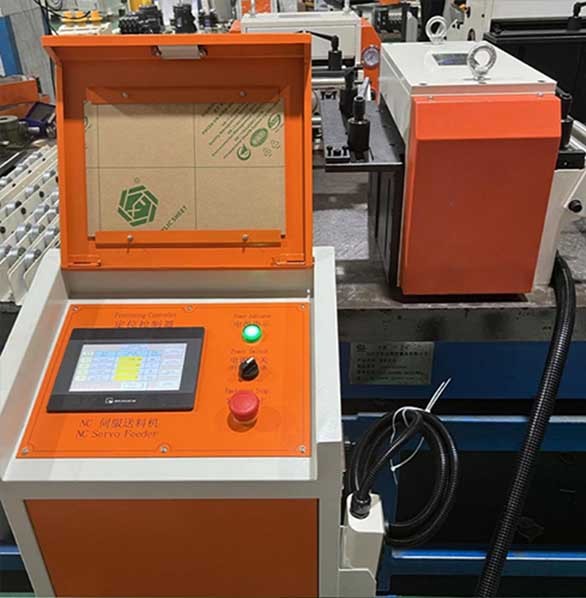

High-speed NC servo feeders represent a significant leap forward in feeding technology, combining the speed of servo motors with the precision of numerical control systems. These advanced press feeders are capable of delivering rapid and accurate material feeding, enabling manufacturers to achieve higher production rates and superior quality output. By harnessing the power of servo-driven mechanisms, high-speed NC feeders have redefined the standards of efficiency and performance in industrial feeding operations.

More info about NC servo feeders by clicking Here.

Key Features and Benefits of High-Speed NC Servo Feeders

The key features of high-speed NC servo feeders include programmable feed lengths, adjustable feed speeds, and precise material positioning capabilities. These coil feeders offer unparalleled flexibility and control, allowing manufacturers to customize feeding parameters according to their specific production requirements. As a type press feeder, the benefits of high-speed NC servo feeders extend beyond speed and accuracy, encompassing reduced setup times, minimal material waste, and enhanced overall productivity.

Enhancing Efficiency Through Advanced Feeding Technology

The integration of advanced technologies such as high-speed NC servo feeders into manufacturing processes has a transformative impact on operational efficiency. By leveraging the capabilities of these cutting-edge coil feeders, companies can streamline their production workflows, minimize downtime, and optimize material utilization. The real-time monitoring and control features of high-speed NC servo feeders enable manufacturers to proactively address issues and ensure continuous operation at peak performance levels.

Driving Innovation and Competitiveness in Manufacturing

High-speed NC servo feeders represent a cornerstone of innovation in the manufacturing industry, empowering companies to push the boundaries of speed, precision, and productivity. By embracing these advancements in feeding technology, manufacturers can differentiate themselves in the market, meet the demands of high-speed production environments, and deliver superior quality products to their customers. The adoption of high-speed NC servo feeders is not just a technological upgrade but a strategic investment in the future success and sustainability of manufacturing operations.

Conclusion

In conclusion, the advancements of high-speed NC servo feeders are revolutionizing the landscape of industrial feeding, setting new standards for speed, precision, and efficiency. By embracing these cutting-edge technologies and harnessing their transformative capabilities, manufacturers can elevate their production processes, drive innovation, and stay competitive in an ever-evolving market. The era of high-speed feeding has arrived, and companies that leverage the power of high-speed NC servo feeders are poised to lead the way towards a future of enhanced productivity and success in manufacturing.