Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Improving Steel Processing Efficiency with NC Servo Feeder Machines

time2024/06/21

- Enhance metal processing efficiency with NC servo feeder machines for precise feeding, automation, and increased productivity in manufacturing.

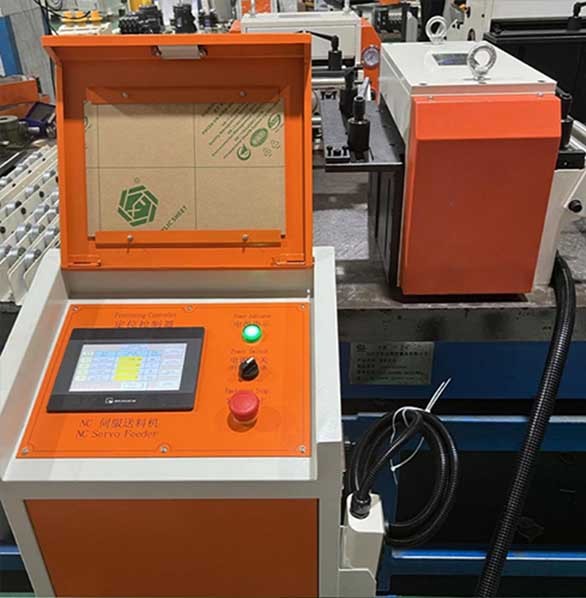

The NC Servo Feeder is a specialized type of coil feeder designed specifically for handling and feeding steel coils. By integrating NC servo feeders into manufacturing operations, the efficiency of steel coil processing can be significantly improved. This guide delves into the various benefits and strategies associated with using NC servo feeder machines in steel coil processing to maximize operational efficiency.

In the realm of steel coil handling, the press feeder plays a crucial role. Among the different types of press feeders available, the NC servo feeder stands out due to its precision and reliability. The NC servo feeder not only ensures accurate feeding of steel coils but also enhances the overall processing speed. This makes the NC servo feeder an indispensable tool in modern manufacturing setups where efficiency is paramount.

Coil feeders are essential in the steel processing industry, and the NC servo feeder represents the pinnacle of coil feeding technology. By utilizing an NC servo feeder, manufacturers can achieve higher throughput and more precise control over the feeding process. The NC servo feeder's ability to handle a wide range of coil sizes and materials further adds to its versatility and value in steel coil processing.

In summary, the NC servo feeder is a highly effective coil feeder that significantly boosts the efficiency of steel coil processing. This guide aims to highlight the advantages of using NC servo feeder machines and provide insights into optimizing their use for enhanced productivity in the steel industry. Whether you are dealing with large-scale operations or smaller production runs, the NC servo feeder offers a reliable and efficient solution for all your coil feeding needs.

Importance of NC Servo Feeder Machines

NC servo feeder machines is important press feeder and play a vital role in steel coil processing by accurately feeding and positioning metal sheets for stamping, punching, and forming operations. Their precision, speed, and automation capabilities contribute to increased productivity, reduced material waste, and improved quality control in metal processing applications. Learn More

Strategies for Enhancing Efficiency of NC Servo Feeder

1. Precision Feeding and Positioning

NC servo feeder machines offer precise feeding and positioning of metal sheets, ensuring accurate alignment and consistent processing results. By optimizing feed parameters, adjusting speed settings, and fine-tuning positioning accuracy, manufacturers can enhance process efficiency and achieve high-quality output.

2. Automation and Integration

Automation features in NC servo feeder machines streamline metal processing workflows by automating material handling, feeding, and synchronization with other equipment. Integrating feeder machines with press systems, control software, and monitoring devices enhances operational efficiency, reduces manual labor, and minimizes production downtime.

3. Speed and Productivity Optimization

NC servo feeder machines enable high-speed processing of metal sheets, leading to increased productivity and throughput in metal processing operations. By adjusting feed rates, optimizing stroke lengths, and implementing multi-stage feeding processes, manufacturers can maximize production efficiency and meet demanding production schedules.

Conclusion

In conclusion, enhancing metal processing efficiency with NC servo feeder machines is essential for achieving optimal productivity, quality, and cost-effectiveness in metalworking industries. By leveraging the precision, automation, and speed capabilities of NC servo feeder machines, manufacturers can streamline processes, reduce lead times, and elevate overall efficiency in metal processing operations.