Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How to max long-term stability maintenance for your 3-in-1 Press Feed Line?

time2024/05/30

- Maximize efficiency and longevity of your 3-in-1 press feed line with proactive maintenance strategies and preventive measures.

In the manufacturing industry, the efficiency and longevity of steel coil handling equipment play a crucial role in ensuring smooth operations and maximizing productivity. One key component that significantly impacts production processes is the 3-in-1 press feed line. This sophisticated machinery is called Decoiler Straightener Feeder or Uncoiler Straightener Feeder that integrates decoiling, straightening, and feeding functions, making it a vital asset in metal stamping and processing operations.

Understanding the Importance of Maintenance of Decoiler Straightener Feeder

Regular maintenance of your 3-in-1 press feed line is essential to prevent unexpected breakdowns, minimize downtime, and extend the lifespan of the equipment. Neglecting maintenance can lead to costly repairs, decreased productivity, and compromised product quality. By implementing a proactive maintenance strategy, you can optimize the performance of your press feed line and enhance overall operational efficiency.

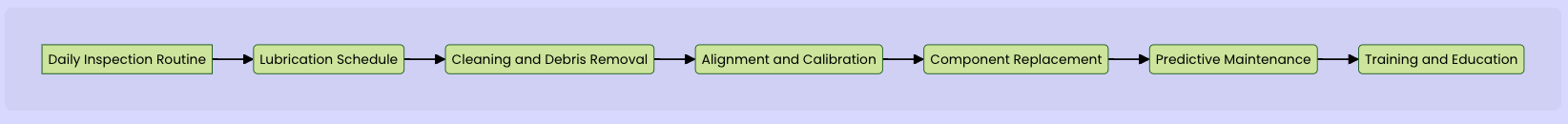

Comprehensive Maintenance Guidelines to Decoiler Straightener Feeder

1. Daily Inspection Routine

Establish a daily inspection routine to check for any signs of wear, damage, or abnormalities in the press feed line components. Pay close attention to the decoiler, straightener, and feeder units to ensure smooth operation and identify potential issues early on.

2. Lubrication Schedule

Proper lubrication is critical to the performance of the press feed line. Develop a regular lubrication schedule based on the manufacturer's recommendations to keep moving parts well-oiled and functioning smoothly. Use high-quality lubricants to prevent friction, reduce wear, and prolong the life of the equipment.

3. Cleaning and Debris Removal

Maintain a clean working environment around the press feed line to prevent debris, dust, and contaminants from affecting the machinery. Regularly clean the components, remove any buildup or residue, and ensure proper ventilation to prevent overheating.

4. Alignment and Calibration

Periodically check the alignment and calibration of the press feed line to ensure precise feeding and processing of materials. Misaligned components can lead to inaccuracies, material waste, and production delays. Invest in professional alignment services to maintain optimal performance.

5. Component Replacement

Monitor the condition of wear-prone components such as feed rollers, straightening rolls, and decoiler mandrels. Replace worn or damaged parts promptly to prevent further damage to the machinery and maintain consistent production quality.

Implementing Preventive Maintenance Strategies

* Predictive Maintenance

Utilize predictive maintenance techniques such as vibration analysis, thermography, and oil analysis to detect potential issues before they escalate. Implementing predictive maintenance strategies can help you anticipate equipment failures, schedule maintenance proactively, and minimize unplanned downtime.

* Training and Education

Invest in training programs for your maintenance staff to enhance their knowledge and skills in servicing and troubleshooting the press feed line. Well-trained technicians can identify problems early, perform maintenance tasks effectively, and ensure the optimal performance of the equipment.

Conclusion

By following a comprehensive maintenance regimen and implementing preventive strategies, you can ensure the long-term stability and efficiency of your 3-in-1 press feed line. Regular inspections, proper lubrication, cleaning, alignment checks, and component replacements are essential practices to maintain the equipment in top condition. Prioritize maintenance to safeguard your investment, optimize production processes, and achieve consistent quality output.