Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Comprehensive Guide to Heavy-Duty Decoilers: Components and Operation

time2024/05/23

- Discover the essential components and workings of heavy-duty decoilers for seamless manufacturing processes.

In the realm of industrial machinery, heavy duty decoilers play a crucial role in the process of unwinding and feeding metal coils into production lines. Understanding the key components and operation of these robust machines is essential for ensuring smooth and efficient manufacturing processes. In this guide, we will delve into the intricate details of heavy-duty decoilers, shedding light on their components and how they function.

A Heavy Duty Decoiler is an industrial machine designed to handle and uncoil heavy metal coils, typically used in steel, aluminum, and other metal processing industries. This equipment features a robust structure and high load-bearing capacity, enabling it to efficiently and safely uncoil large, heavy coils. The Heavy Duty Decoiler is equipped with an automatic control system that ensures precise tension control and adjustable speed, guaranteeing stability and quality in subsequent processing steps. It is easy to operate, has low maintenance costs, and is an essential piece of equipment for heavy metal processing. Learn More

Key Components of Heavy Duty Decoilers

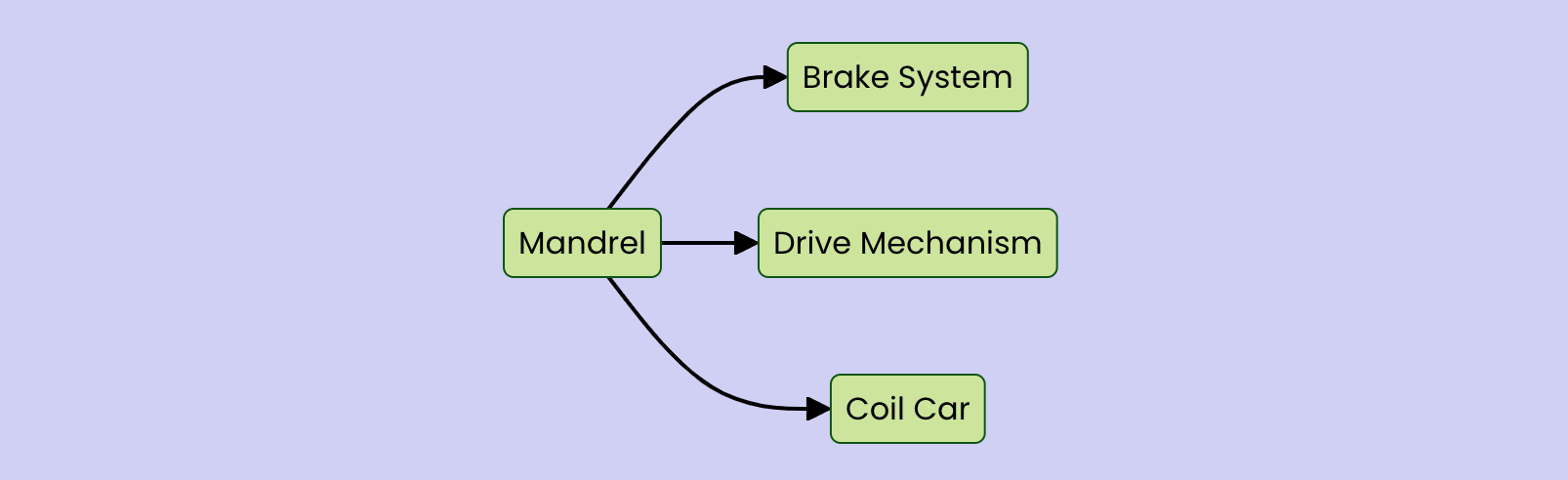

Mandrel

The mandrel is a central component of a heavy-duty decoiler, responsible for holding and supporting the metal coil. It is designed to rotate freely, allowing the coil to unwind smoothly during the feeding process. The mandrel's construction and material quality are critical factors in ensuring the stability and durability of the decoiler.

Brake System

A reliable brake system is essential for controlling the unwinding speed of the metal coil. The brake system in a heavy-duty decoiler helps prevent overfeeding and ensures precise tension control during operation. It consists of various components such as brake pads, discs, and a control mechanism to regulate the braking force effectively.

Drive Mechanism

The drive mechanism powers the rotation of the mandrel and facilitates the unwinding of the metal coil. It is typically equipped with a motor, gearbox, and transmission system to provide the necessary torque and speed for efficient operation. The drive mechanism plays a vital role in maintaining consistent feeding rates and minimizing downtime.

Coil Car

A coil car is a movable platform that assists in loading and unloading metal coils onto the decoiler. It enhances operational efficiency by enabling quick and safe coil changes, reducing manual handling and downtime. The design and functionality of the coil car contribute significantly to the overall productivity of the decoiling process.

Operation of Heavy Duty Decoilers

Loading the Metal Coil: The operator uses the coil car to transport the metal coil to the decoiler and positions it securely on the mandrel.

Securing the Coil: The mandrel clamps the metal coil in place, ensuring proper alignment and tension for smooth unwinding.

Activating the Brake System: The operator engages the brake system to control the unwinding speed and maintain consistent tension throughout the feeding process.

Starting the Drive Mechanism: The drive mechanism is activated to rotate the mandrel, initiating the unwinding of the metal coil into the production line.

Monitoring Operation: The operator oversees the decoiling process, adjusting the brake system and drive mechanism as needed to optimize performance and prevent any issues.

By understanding the key components and operation of heavy-duty decoilers, manufacturers can enhance their production processes and achieve greater efficiency and productivity in metal forming operations.

Conclusion

In conclusion, heavy duty decoilers are indispensable assets in metal processing industries, and a comprehensive understanding of their components and operation is essential for maximizing productivity and ensuring seamless manufacturing processes. By implementing best practices and maintenance procedures, manufacturers can optimize the performance of their decoilers and achieve superior results in steel coil handling and feeding operations.