Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

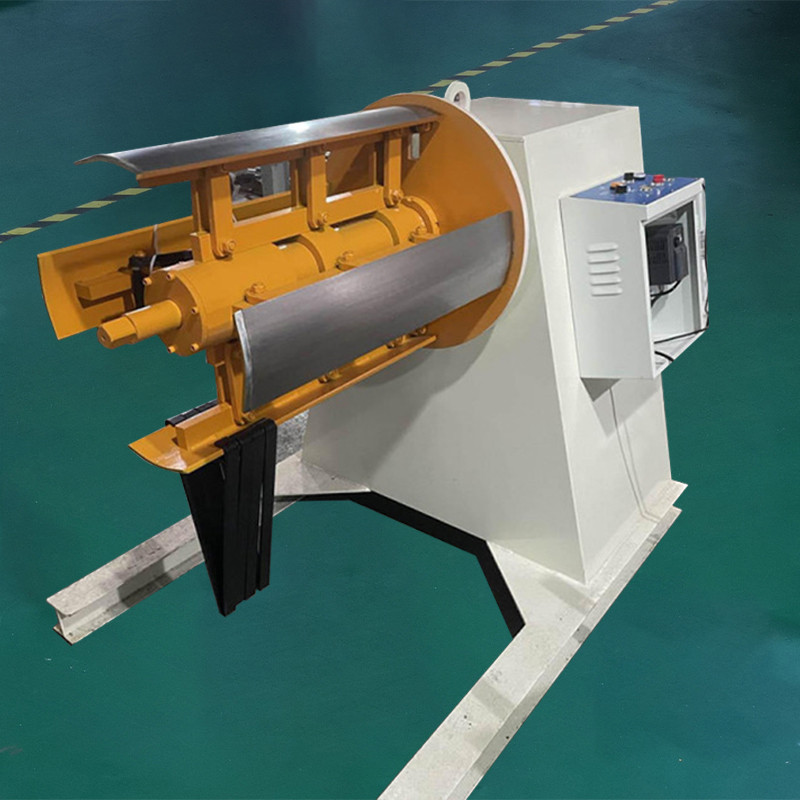

Revolutionize Your Operations with the Latest Fully Automatic Heavy-Duty Uncoiler

time2024/05/09

- Stay ahead of the competition and revolutionize your production processes with Fanty Machine heavy-duty uncoiler.

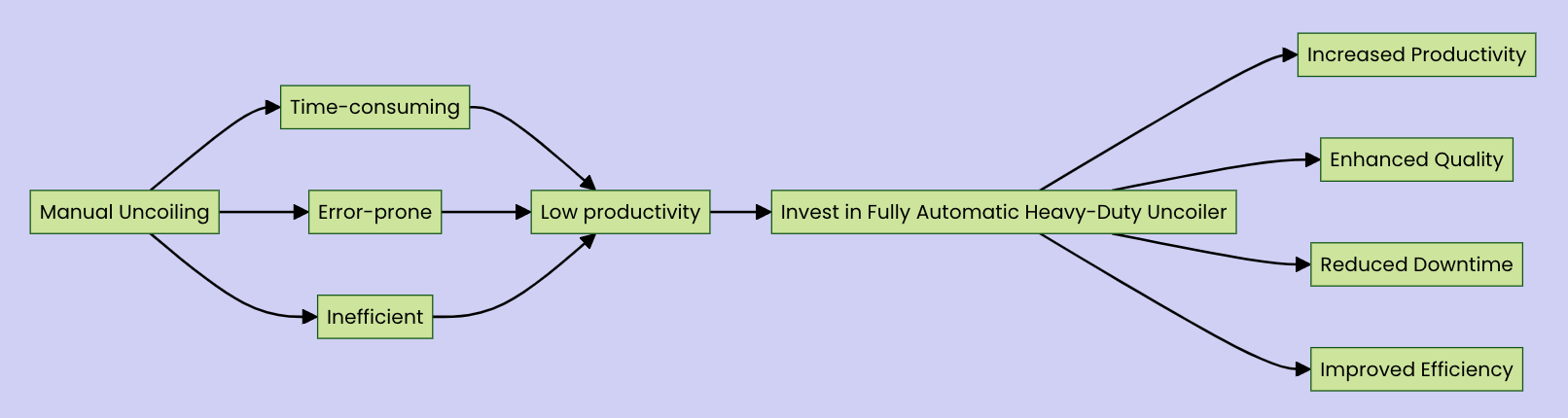

In today's fast-paced industrial landscape, efficiency and precision are key factors in staying ahead of the competition. One of the most critical components in metalworking operations is the uncoiling process, which sets the stage for the entire production line. To enhance your operations and streamline your workflow, investing in a cutting-edge fully automatic heavy-duty uncoiler is a game-changer.

The Power of Automation in Uncoiling

Gone are the days of manual uncoiling processes that are not only time-consuming but also prone to errors. With a fully automatic heavy-duty uncoiler, you can significantly boost your productivity and accuracy. The automation technology integrated into these machines ensures seamless operation, precise tension control, and consistent performance, leading to higher output and superior quality products.

Key Features and Benefits of Heavy-duty uncoiler

1. Advanced Control Systems

The fully automatic heavy-duty uncoilers come equipped with state-of-the-art control systems that allow for easy customization of parameters such as speed, tension, and direction. This level of control ensures optimal performance and minimizes material waste.

2. High-Speed Operation

With the ability to uncoil metal strips at high speeds, these machines can keep up with the demands of modern production environments. This results in faster turnaround times and increased efficiency.

3. Heavy-Duty Construction

Built to withstand the rigors of heavy-duty industrial use, these uncoilers are constructed from durable materials that guarantee longevity and reliability. Their robust design ensures stable operation even under high loads.

4. Safety Features

Safety is paramount in any industrial setting, and fully automatic heavy-duty uncoilers are equipped with a range of safety features such as emergency stop buttons, overload protection, and interlocking systems to prevent accidents and protect operators.

Enhancing Your Bottom Line

By investing in a cutting-edge fully automatic heavy-duty uncoiler, you are not just upgrading a piece of equipment; you are transforming your entire production process. The increased efficiency, precision, and reliability that these machines offer can have a significant impact on your bottom line by reducing downtime, minimizing material waste, and improving overall product quality.

In conclusion, embracing automation in the form of a fully automatic heavy-duty uncoiler is a strategic move that can propel your operations to new heights of success. Stay ahead of the curve and revolutionize your metalworking processes with this cutting-edge technology.

Remember, in the competitive world of metalworking, innovation is the key to success. Upgrade to a fully automatic heavy-duty uncoiler today and experience the difference firsthand.