Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Operating Guidelines for the Decoiler

time2024/04/19

- The most popular uncoiling device in the stamping manufacturing line is the decoiler. Learning the guidelines for using the decoiler is important during press line.

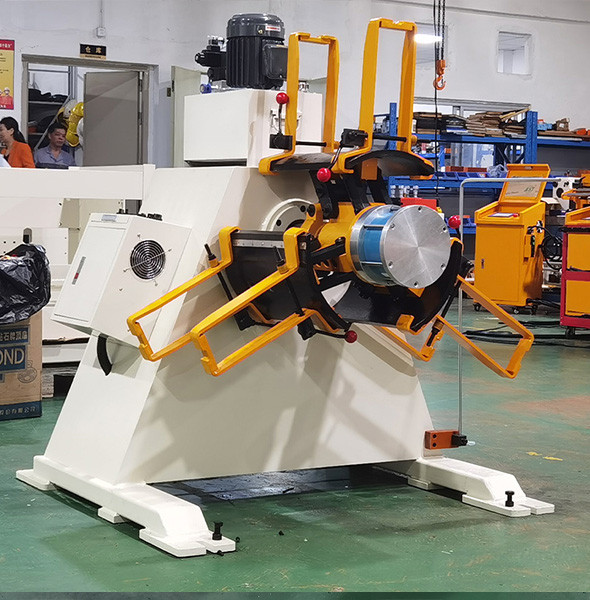

The most popular uncoiling device in the stamping manufacturing line is the decoiler because of its high load capacity, low failure rate, and reasonable cost. Electricity governs its operation; the frequency converter regulates the speed of uncoiling while simultaneously enabling the decoiler's start and stop via 24V contact induction, ensuring the machine runs normally as a whole.

Guidelines for using the Decoiler:

2. Depending on the material thickness and the location of the matching leveler or feeder machine that follows, adjust the distance between the decoiler and that machine. This is done to ensure that the discharge enters the feeder or leveler equipment smoothly. A certain waiting area needs to be changed based on the feeding length if the coil feeder machine is the sole one being used. The distance from the feeding port of the feeding device is 4 to 4.5 meters when the decoiler's center height is about equivalent to the punching machine's working surface. Increase the feeding distance and change the discharge direction appropriately if the center of the decoiler and the punch press's working surface are too high or too low.

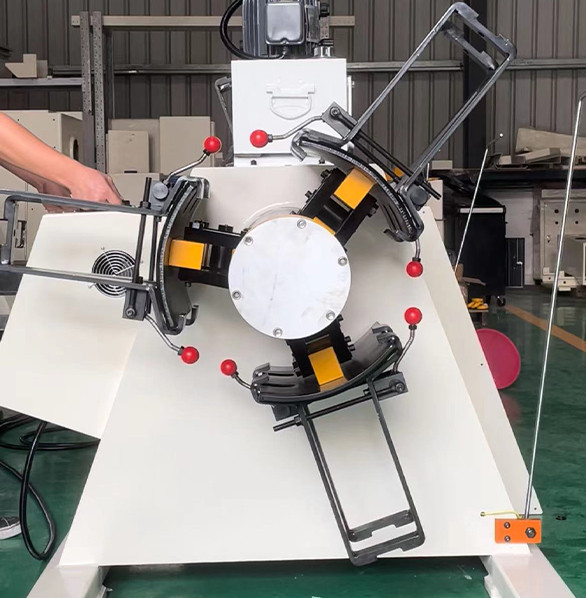

3. To make the support plate's diameter smaller than the material's inner diameter, turn the decoiler's handle counterclockwise. Place an A-type iron baffle plate at each corner, place the coil material there, twist the decoiler's handle clockwise, tighten the coil material's inner ring, and place the material baffle plate on the remaining two material plates. It should be mentioned that the material blocking plate should not clamp the coil material too tightly, as this would impair the discharge; instead, a gap of 2 to 5 mm should be left. To securely grasp the coil material, turn the decoiler's handle clockwise.

5. When operating automatically, the feeding speed is directly adjustable on the panel and is managed by induction. If you need to use the jogging feature, first select the option to manually rotate the panel in either forward or backward direction. Then, press the jogging button; the speed can also be changed.

Control instructions for an electric control box:

Status of the power switchWorking decoiler status:

"OFF" The decoiler is unable to function when the power supply is taken off.

MANUThe "Forward" or "Reverse" button controls the decoiler's forward and backward rotation when it is in the jog mode.

AUTOMATIONThe decoiler is powered by an induction circuit and operates automatically.

6. Press the emergency stop switch right away if the decoiler's feeding is discovered to be abnormal. The press punching machine will likewise stop at that moment. The press punching machine cannot be formally started until the emergency stop switch has been reset, or unscrewed, once the abnormality has been restored.

The six decoiler operation directions are listed above. When the decoiler needs to be started for work, it is important to follow the operating instructions precisely to prevent the decoiler from going out. Please get in touch with Fanty Machinery directly if you have any more questions concerning the decoiler.