Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

What's the different between flat uncoiler and normal decoilers ?

time2024/01/23

- Normal Decoilers and flat decoiler, commonly used in the stamping industry, facilitate the automatic uncoiling and feeding of coil materials for subsequent processes.

The types of decoiler equipment that are more frequently used in the stamping business are standard decoilers and a flat decoiler (sometimes called a disc decoiler). Its primary purpose is to enable the coil material to be automatically uncoil and fed in preparation for the leveling (or feeding) procedure that follows.

These two versions, however, each have a different range of material applications. Decoilers are useful for uncoiling materials that are thick, heavy, and wide. There is a fair amount of customisation. Typically, the uncoiling speed ranges from 15 to 18 m/min. The flat decoiler can uncoil narrow materials and thin plates at a speed of up to 30 meters per minute. Since some of these two decoilers' actual application scopes overlap, many clients may be unsure about which sort of decoiler to choose at this point.

Right now, it's important to comprehend the differences between the two decoilers so that you may make an informed decision based on your needs. The following articles can provide you with a more thorough understanding of the decoiler and help you grasp its many differences in greater depth.

The differences between the two decoilers are explained in detail below:

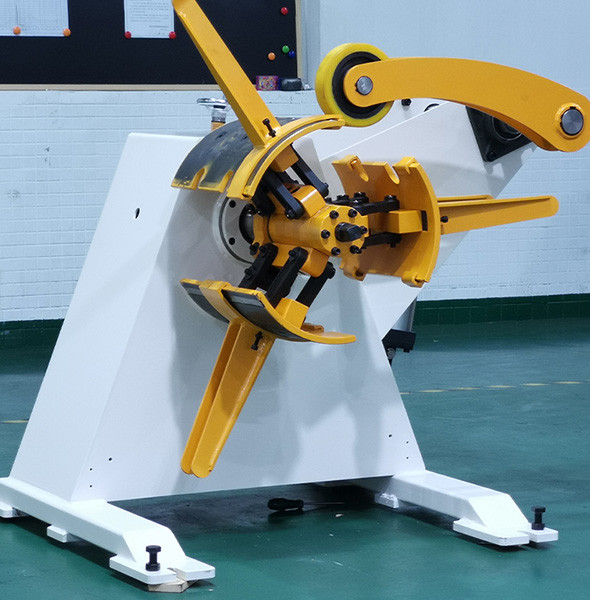

1. The decoiler is a vertical uncoiling device that expands and contracts like a reel, and it can handle materials with thicknesses between 0 and 3.0 mm. Depending on the machine model, the relevant material thickness and width can vary greatly, with the material width and thickness range reaching up to 6.0 mm and 10-2000 mm, respectively, after the addition of optional devices such pressing arms.

A horizontal uncoiling device, the flat decoiler's applicable material range is 0-1.0 mm, whereas its standard applicable material range is 0-120 mm. The appropriate material width for thin materials is limited to 300mm.

2. The expansion-shrinking reel is used by the decoiler for tensioning and unloading, and before it can be utilized, the coil must be placed into the expansion-shrinking reel to adjust the tension. Consequently, the inner diameter is required; the decoiler's standard ranges from 450 to 530 mm (the national standard coil's inner diameter is 508 mm on average).

The coil can be placed directly on the rotating disc in the flat decoiler, which uses the disc feeding method. The coil's inner diameter is not restricted.

3. The decoiler standard uses a 24 V induction frame induction mechanism, and for the automatic operation to halt, the material must come into contact with the induction rod (induction frame). After leaving the sensing rod, it begins to operate automatically, which could scratch the material's surface (the photoelectric induction method can be replaced).

The micro-motion induction method is the typical induction technique used with flat decoilers. The disc load plate begins to operate after the material pulls the swing rod. After the pendulum is reset, the material is no longer being pulled, and the disc load plate also ceases operating. The disc load plate does not come into direct contact with the material's surface and will not cause any scratches.

For any questions, you can get in touch with us directly at fanty..........com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://..........com/@fantydecoilerfeeder

Facebook: https://..........com/Fanty1229/

Linkedin:https://..........com/company/fantydecoilerfeeder