Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Safety measures when using the uncoiler

time2023/12/27

- In the stamping business, the uncoiler has become an increasingly common main unwinding piece of equipment.

Taking precautions when using the uncoiler

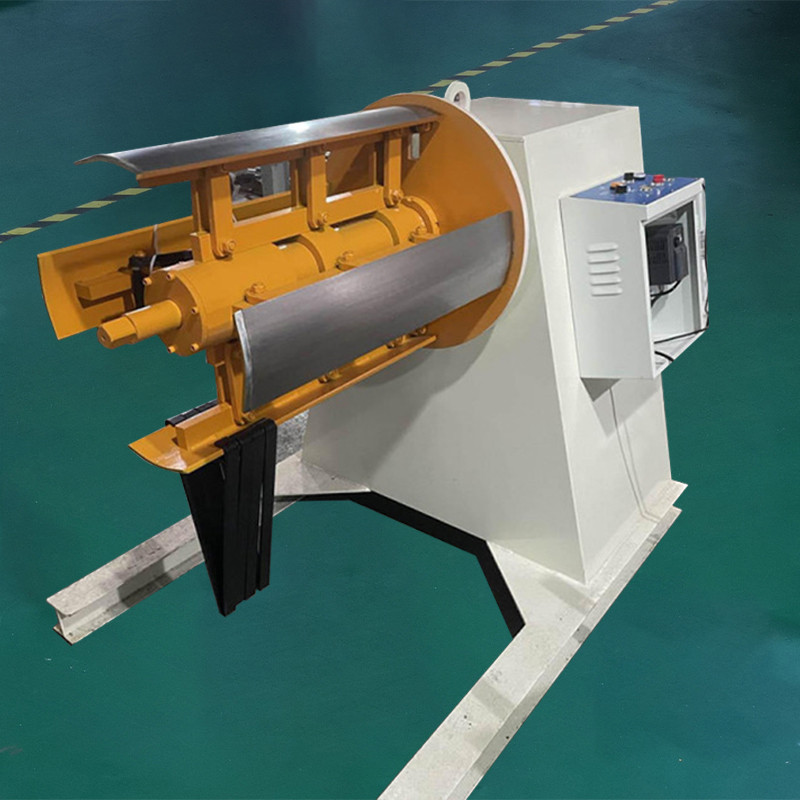

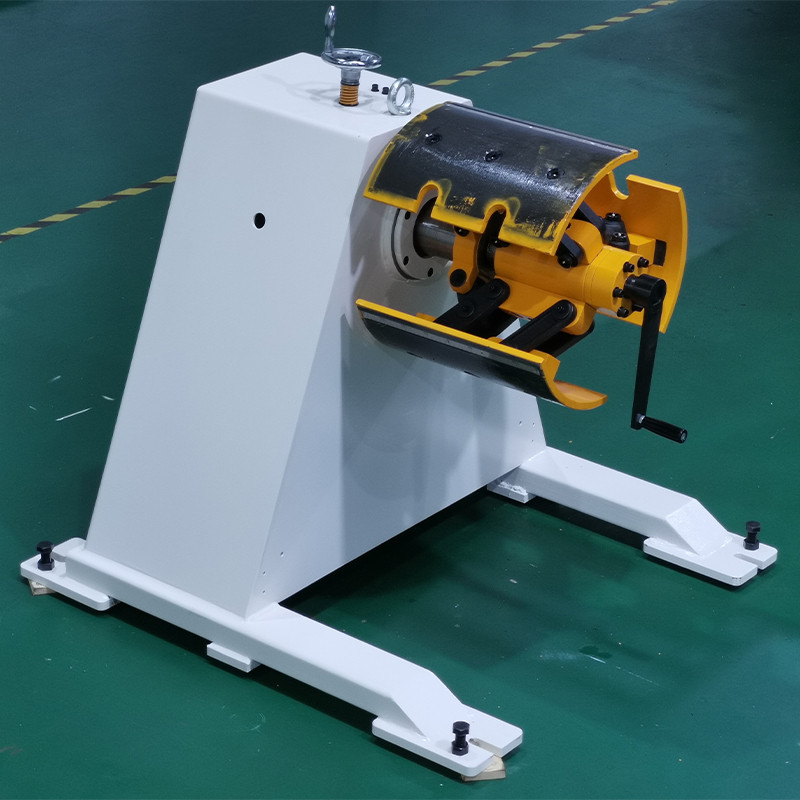

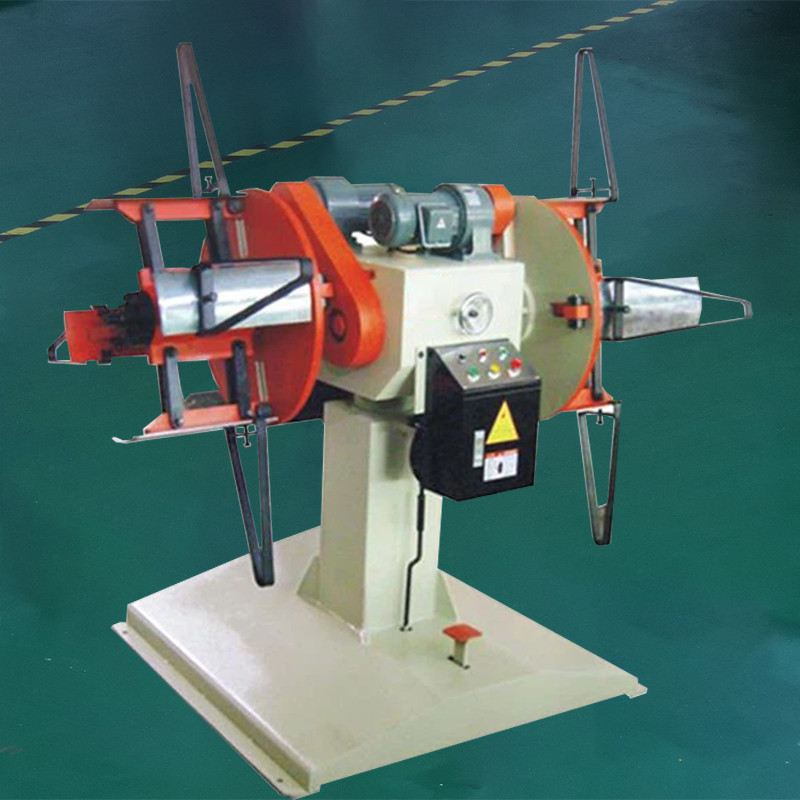

In the stamping business, the uncoiler has become an increasingly common main steel coil handling equipment for punch press line. It is also called decoiler or decoiler machine. Understanding how to operate, maintain, repair, and maintain an uncoiler is crucial since when used incorrectly, it can easily result in various safety incidents. Moreover, you can learn more decoiler info here.

As a result, FANTY Machinery will go over the safety measures for using the uncoiler in detail with our clients:

1. To guarantee that the uncoiler will not look biased when uncoiling, it is necessary to make sure that, when it is moving and positioned, the center of the supporting tile plate carrying the coil material is on the same line as the following matching machine.

2. Verify if the coil's inner and outer diameters are within the uncoiler's applicable range by looking at its breadth, thickness, weight, and other material parameters. In order to guarantee that the inner diameter of the material is the metal surface that is closest to the supporting tile, simultaneously remove any edge layers, such as paper circles, from the inner diameter of the material roll before feeding.

3. Take caution not to collide with the uncoiler's expansion spindle, electric box, or other components when loading it with a forklift or crane to prevent harm to the device. At the same time, after feeding is finished, make sure the uncoiler's expansion and contraction drum has stretched the material coil all the way, and use the decoiler machines to effectively stop the material.

4. When operating the uncoiler, professional staff should do the operation and the operation method should be closely adhered to by the operation manual. Simultaneously do the heavy-duty uncoiler's pre-operational inspection, operation-related observation, and post-operation review to guarantee its dependability and safety. Additionally, it is not permitted to touch the uncoiler's rotating component while it is in use. It must be stopped right away for inspection and repair if there is any anomaly.

What Uncoiler/Decoiler Does FANTY Manufacture now?

The safety measures for using the decoiler machines are listed above. You can reach us personally at fanty..........com with any inquiries, and we'll assist you in resolving the issue.

Click Here for more information about uncoiler machine for your press line.

For any questions, you can get in touch with us directly at fanty..........com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://..........com/@fantydecoilerfeeder

Facebook: https://..........com/Fanty1229/

Linkedin:https://..........com/company/fantydecoilerfeeder