Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Is it possible to use an uncoiler to uncoil non-conductive materials?

time2023/12/25

- The material's surface must be conductive in order for this induction method to accomplish its automatic start and stop action; hence, non-conductive material cannot be uncoiled using a conventional.

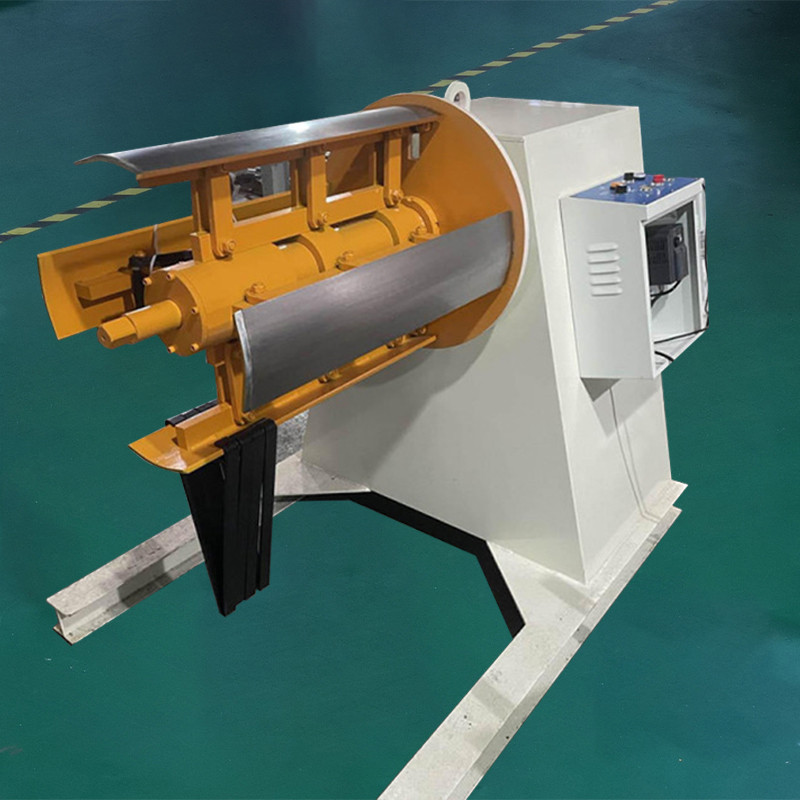

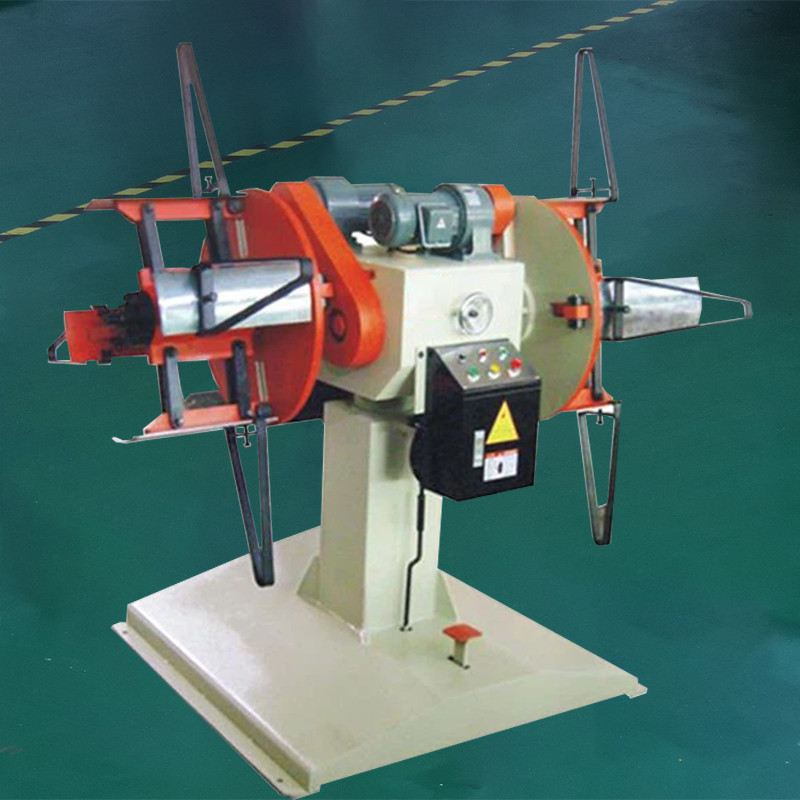

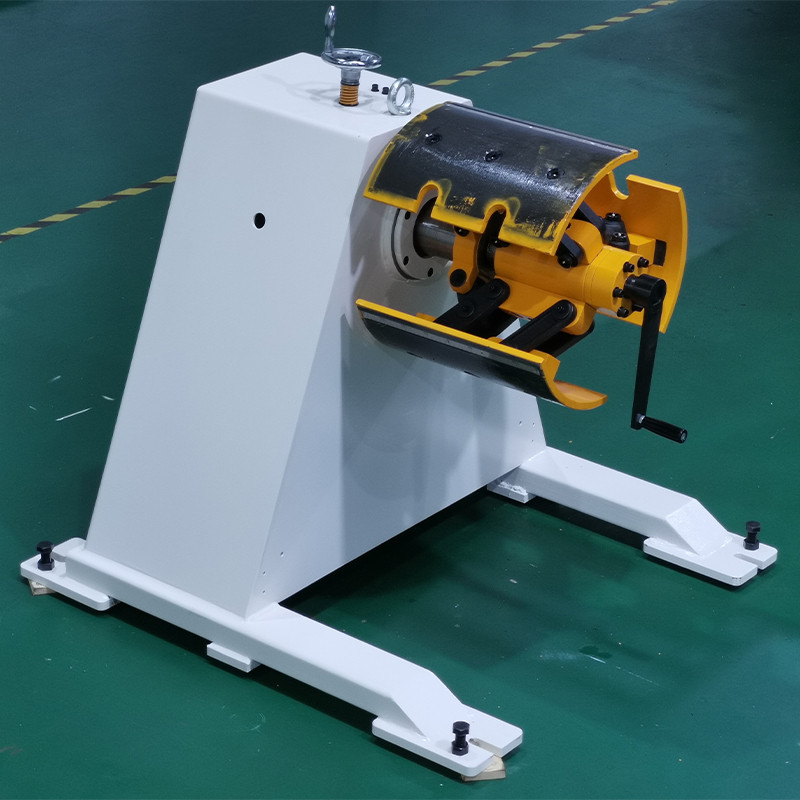

As steel coil handling equipment, decoiler is a necessary machine for the punch pre line. When a customer buys an uncoiler, FANTY Machinery will inquire about the material's inner and outer diameters, width, thickness, and other basic characteristics. It will also inquire about the material's film cover and conductivity. More uncoiler specification, pls learn here.

Since non-conductive materials cannot be uncoil by a typical uncoiler, this question must be answered. Currently, 12V DC induction voltage is primarily used by normal uncoilers. The material's surface must be conductive in order for this induction method to accomplish its automatic start and stop action; hence, non-conductive material cannot be uncoiled using a conventional.

Of course, unwinding non-conductive materials is also quite easy. By altering the uncoiler's sensing mechanism, it is possible to achieve automatic unwinding of silicon steel sheets, non-conductive materials, surface-mounted film materials, and non-metallic materials. The uncoiler's induction mode can vary in three different ways, primarily: by proximity switches, photoelectric switches, and micro switches.

1. The most popular induction technique for uncoiling non-conductive materials is the micro switch induction method, which takes the role of the uncoiler.

2. To unwind non-conductive metal materials, the proximity switch induction method takes the place of the uncoiler (note that non-metallic materials cannot be unwound with this method).

3. The photoelectric switch induction method, which is utilized to uncoil non-conductive metal materials and non-metal materials with high surface precision, takes the role of the uncoiler. Diffuse photoelectricity and through-beam photoelectricity are the two possibilities. The idea is that after a given amount of sagging, the material blocks the photoelectric switch's light, which causes the uncoiler to halt.

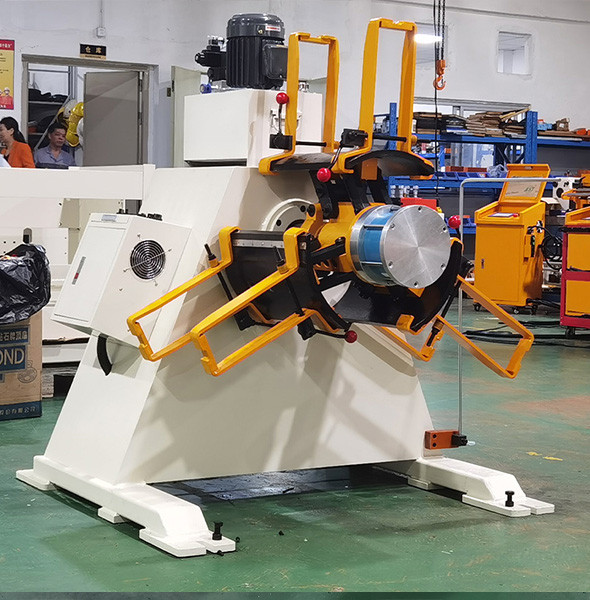

What Uncoiler/Decoiler Does FANTY Manufacture?

If you have any other question or inquiry, pls contact us fanty..........com.

For any questions, you can get in touch with us directly at fanty..........com, and we'll help you figure out the problem.

For additional details regarding the equipments, see this link.

Follow FANTY Channel:

Youtube: https://..........com/@fantydecoilerfeeder

Facebook: https://..........com/Fanty1229/

Linkedin:https://..........com/company/fantydecoilerfeeder