Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

How do I choose the model to use when rewinding using an uncoiler?

time2023/12/19

- Explore our expert guide on selecting the ideal decoiler model for precise metal coil rewinding. Discover key considerations for optimizing your metal processing operations.

Decoiler Selection for Efficient Metal Coil Rewinding: Tailoring Solutions to Material Specifications

A decoiler also is called uncoiler for steel coil handling during the punch press line. Explore the nuances of decoiler selection for metal coil rewinding, from compact uncoiler models for scrap tape to heavy-duty decoiler options for thick and wide materials. Optimize your rewinding processes based on material characteristics and production requirements.

In the realm of metal coil rewinding, the choice of decoiler machines play a pivotal role in achieving optimal results. Whether dealing with scrap tape or thick, wide materials, tailoring the decoiler selection to material specifications is key. Let's delve into the intricacies of various decoiler machines designed to cater to different needs.

1. MT Model Decoiler for Scrap Tape:

For scrap tape and narrow materials with a width of less than 200mm and a weight under 200kg, the MT-type decoiler is the ideal solution. Compact in design and occupying minimal space, this model provides an efficient and cost-effective solution for rewinding scrap material. The ease of induction method switching adds versatility to its functionality.

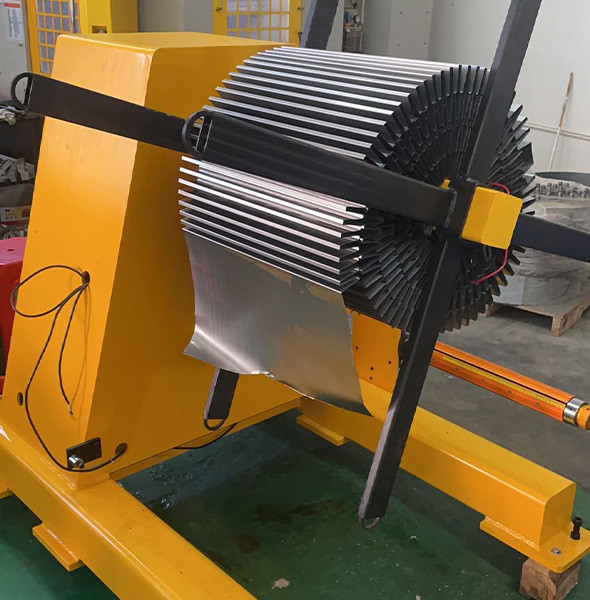

2. Heavy Duty Decoiler for Thick and Wide Materials:

When dealing with thick and wide materials, a heavy-duty, standard type decoiler comes into play. This robust model is engineered to handle looped materials with substantial weight. Its versatility allows tailoring to specific customer needs, ensuring a seamless and customized rewinding process. Learn more.

3. Double-Station Decoiler for Effective Waste Rewinding:

Efficiency in waste rewinding is achieved through the use of a double-station decoiler, significantly reducing downtime. This innovative solution enhances productivity by enabling continuous rewinding, making it a valuable asset for streamlined operations.

As you embark on optimizing your metal coil rewinding processes, consider the unique advantages offered by these specialized decoiler machines. Tailor your selection based on the specific characteristics of your materials and production requirements for a more efficient and cost-effective operation.