Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Unraveling Efficiency: The Role of a Decoiler in Coil Handling

time2020/11/03

- The decoiler machine takes center stage as a crucial player, unraveling the efficiency that lies at the heart of seamless coil handling.

In the realm of metalworking, where precision and speed are paramount, the decoiler emerges as a linchpin in the coil handling process. This article peels back the layers to unveil the efficiency woven into the very fabric of decoiler functionality.

Understanding the Basics:

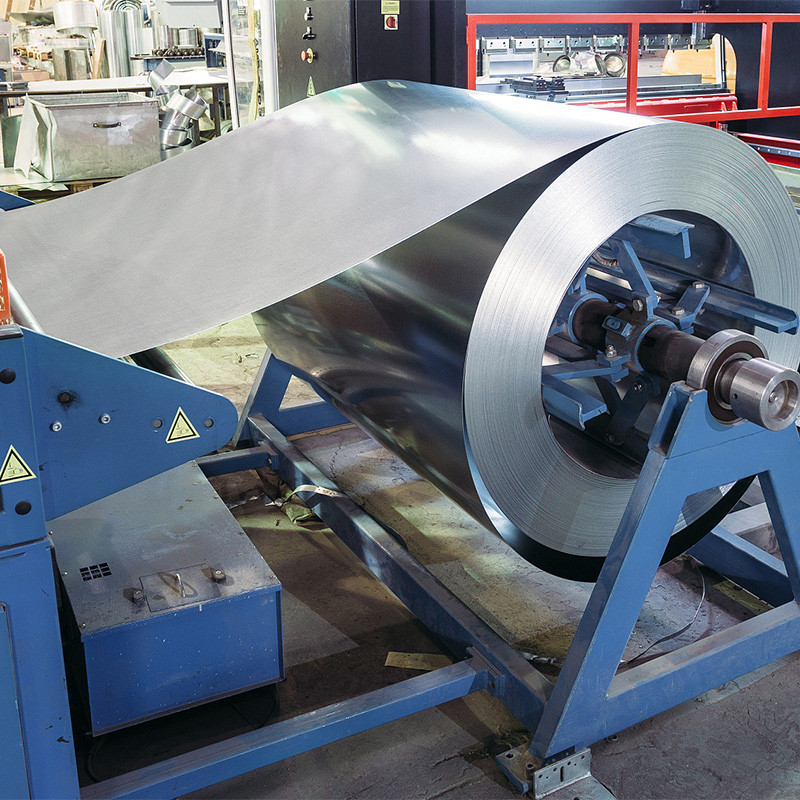

At its core, a decoiler machine is designed to do one thing exceptionally well — unwind coiled steel with precision. The process begins with the loading of steel coils onto the decoiler, setting the stage for a streamlined journey through the production line.

Key Functions

Uncoiling Precision:

* The primary task of a decoiler is to delicately and precisely unwind coiled steel, ensuring a consistent and controlled release of material for downstream processes.

Tension Control:

* Employing advanced tension control mechanisms, decoilers mitigate the risk of material deformation or breakage, contributing to the overall quality of the end product.

Material Feed Accuracy:

* A well-calibrated decoiler ensures accurate material feed, aligning with the demands of subsequent manufacturing steps and minimizing waste.

Enhancing Operational Efficiency

Minimizing Downtime:

* With quick and efficient coil changeovers, decoilers play a pivotal role in minimizing downtime, optimizing production efficiency, and meeting tight manufacturing schedules.

Reducing Material Waste:

* Through precise tension control and accurate material feed, decoilers contribute to the reduction of material waste, positively impacting both cost-effectiveness and environmental sustainability.

Advanced Features and Innovations

Automated Coil Loading:

Modern decoilers often come equipped with automated coil loading systems, further streamlining the production process and reducing the need for manual intervention.

Integration with Industry 4.0:

Decoilers are evolving with the industry, integrating smart technologies and data analytics as part of the Industry 4.0 revolution. This allows for real-time monitoring, predictive maintenance, and enhanced operational insights.

What Decoiler/uncoiler do we have?

Designed for standard coil unwinding, capable of handling a range of materials and coil sizes.

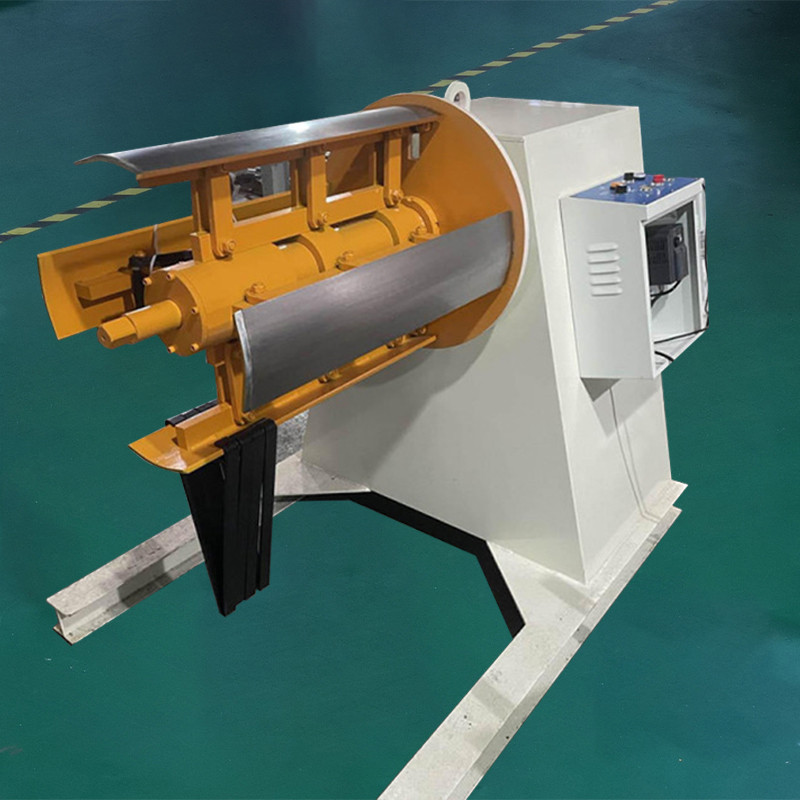

Equipped with a hydraulic system to efficiently handle heavy coils, offering precise control during unwinding.

Engineered for substantial loads and larger coils, providing stability and reliable performance.

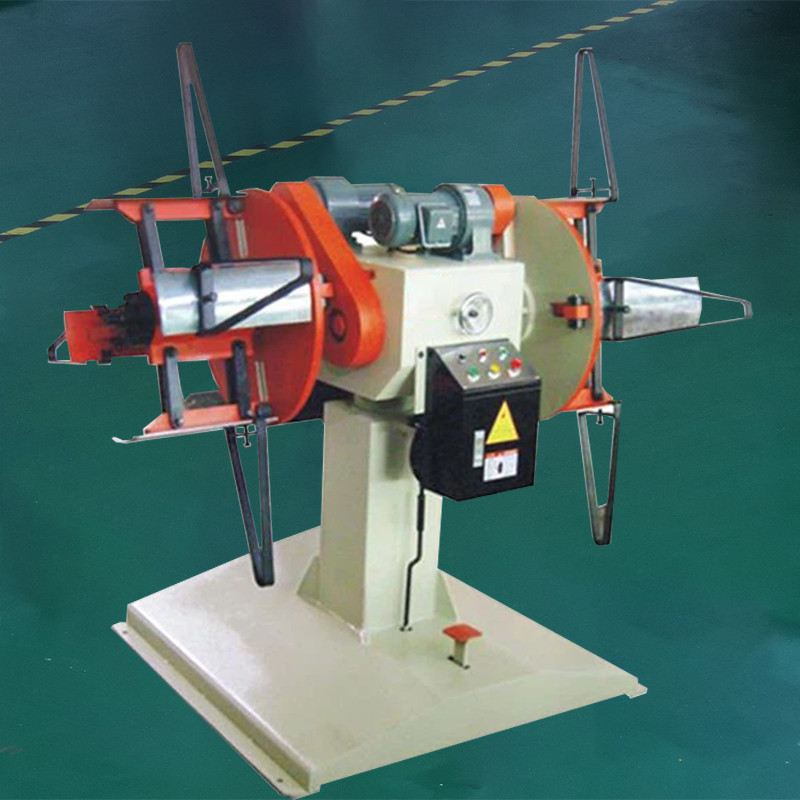

Simultaneously unwinds two coils, reducing setup time and boosting productivity.

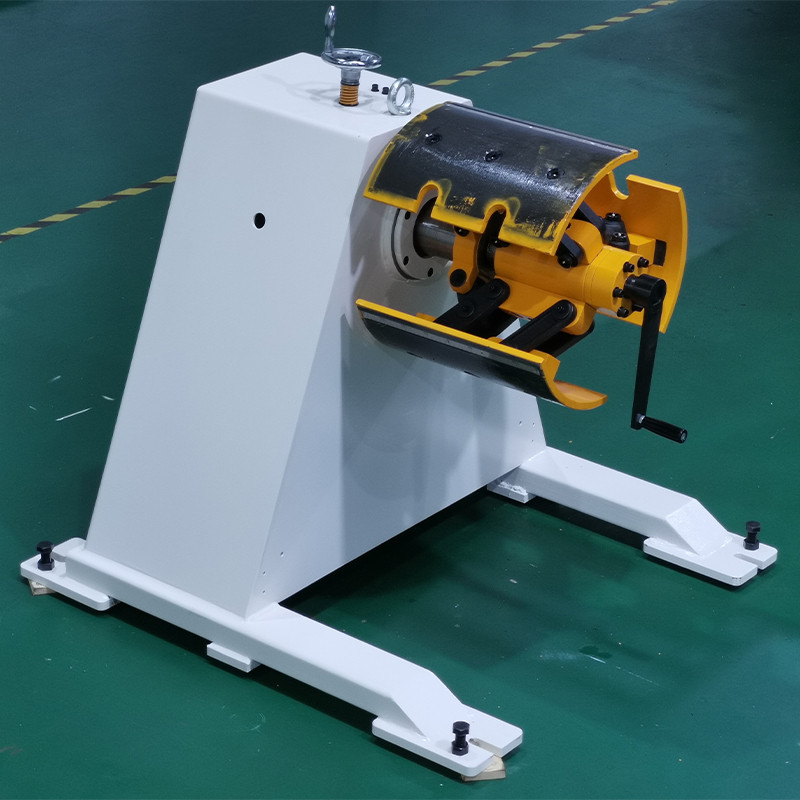

Operated manually, suitable for smaller-scale applications or workshops with intermittent coil handling.

Applications Across Industries

Steel Manufacturing:

In the steel industry, decoilers are indispensable for processing a wide range of steel coils, from heavy-duty materials to thinner gauges, catering to diverse manufacturing needs.

Automotive Sector:

Automotive manufacturing relies on decoilers to handle steel coils efficiently, ensuring precision in the production of components ranging from body panels to intricate parts.

Conclusion

As we unravel the efficiency embedded in the role of a decoiler in coil handling, it becomes evident that this seemingly humble equipment plays a pivotal role in shaping the landscape of modern manufacturing. From its fundamental functions to the integration of cutting-edge technologies, the decoiler stands as a testament to the industry's relentless pursuit of efficiency, precision, and sustainability.