Search This Supplers Products:Decoiler MachinePress FeederDecoiler StraightenerDecoiler Straightener FeederPunch Press

Why a punch servo feeder is necessary?

publisherROYCE

time2014/06/13

- The servo feeder is a high-efficiency press feeder used in both light and heavy industries to help with punch feeding.

What's a servo feeder ?

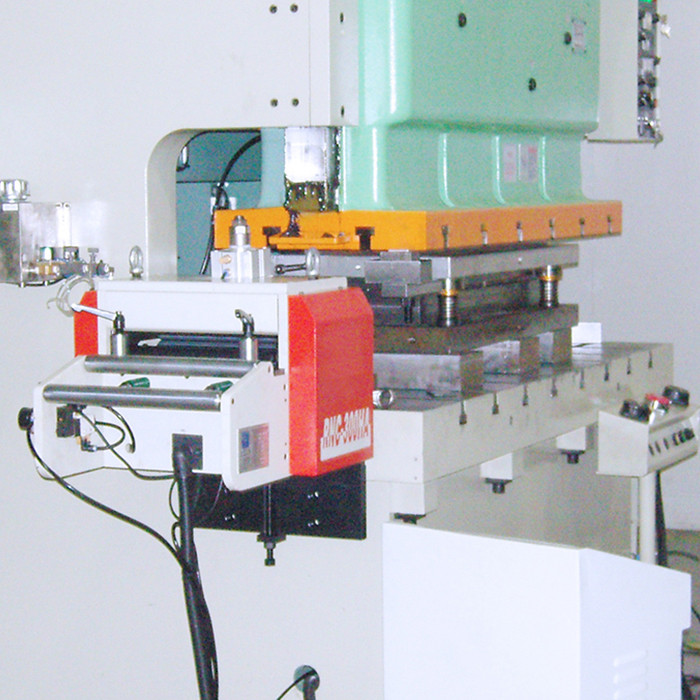

The servo feeder, one type press feeder, is a high-efficiency tool used in both light and heavy industries to help with punch feeding. When employing a punching machine for traditional stamping manufacturing, a single die must be matched to the punching machine, and all processing and production must be done manually using manual feeding. We shall take the lead. Please explain what a punch is to me first. A forming press, commonly referred to as a punch press, is a punching press. They are made to be used for a variety of hydraulic pressure processes, including punching, forming, deep drawing, trimming, fine blanking, shaping, riveting, and extrusion. widely used in hardware parts for transportation (automobiles, motorcycles, bicycles), electronics, communications, computers, home appliances, furniture, and other stamping and forming.

What advantages can a punch servo feeder offer?

In contrast to earlier times, stamping business owners did not have a great need for finished goods. Today's stamping production is moving toward high efficiency, high precision, and high volume, so they must be flexible to suit consumer needs as well as the growth of various industries and machine tools. Therefore, one of the most significant and profitable ways to increase productivity and support businesses in their endeavors is to use automated equipment with punch presses to accomplish completely automated stamping output. It can significantly raise the production effectiveness and essential competitiveness of stamping businesses. When compared to the conventional use of punched sheets, the issue of hand feeding has risen to the fore.

● Greater accuracy and durability

The punch press can create parts with greater consistency thanks to the punch servo feeder's effective operation. The punch servo feeder has a positioning accuracy of 0.05mm or less, which is perfect and also increases the punch's tool life. The machine's continuous high-precision feeding method also enables it to lower the possibility of producing goods that don't meet specifications and losing scrap. The cost of the coil is considerably less than that of the sheet, and the leftover scrap from stamping is wound up by subsequent rewinding machinery, which can be used to its fullest. This can increase quality while lowering production costs and boosting the market competitiveness of stamping businesses.

● Greater effectiveness

The automatic punching production line frequently has a production efficiency that is hundreds of times more than manual punching. To guarantee the consistent quality of the end product, a unique relaxation mechanism eliminates the accumulated error of each stage.

● Safety

The punch press's automated production line uses coil material, which can fully automatically realize uncoiling, leveling, and feeding. This completely automates the feeding operation used in the continuous die stamping process, effectively eliminating the possibility of safety accidents. completely removes safety risks.